Gate valves are essential components in fluid control systems, renowned for their simplicity, durability, and reliable shut-off capabilities. Widely used in industries like water distribution, oil and gas, and fire protection, gate valves offer minimal flow resistance and robust performance. At KFTE Valves, we provide high-quality gate valves designed for diverse applications. This guide explores what gate valves are, their applications, types, operation, and how they compare to ball valves and backflow preventers, answering common questions to help you make informed decisions.

A gate valve is a linear-motion isolation valve that stops or allows fluid flow by raising or lowering a gate-like disc (wedge) within the valve body. Named for its gate-like closure element, it provides a tight shut-off with minimal pressure drop when fully open, making it ideal for on/off applications rather than flow regulation.

Key Features:

Full-Port Design: Matches pipe diameter for unobstructed flow.

Low Flow Resistance: Minimal pressure drop when fully open.

Bi-Directional: Shuts off flow in either direction.

Durability: Simple, robust design for long service life.

Standards Compliance: Meets AWWA C509, API 600, and other industry standards.

Gate valves are primarily used for isolating fluid flow in pipelines, offering a quick and secure shut-off. Their full-bore design ensures minimal obstruction, making them suitable for applications requiring straight-line flow. Common uses include:

Water Distribution: Isolating sections during maintenance or rerouting flow in municipal systems.

Oil and Gas: Shutting off high-pressure pipelines in processing plants.

Fire Protection: Controlling water flow in sprinkler systems.

Industrial Processes: Managing fluids in chemical, power, and manufacturing plants.

Wastewater Treatment: Isolating flow in treatment facilities.

Note: Gate valves are not suitable for throttling due to potential vibration and damage to the wedge or seat.

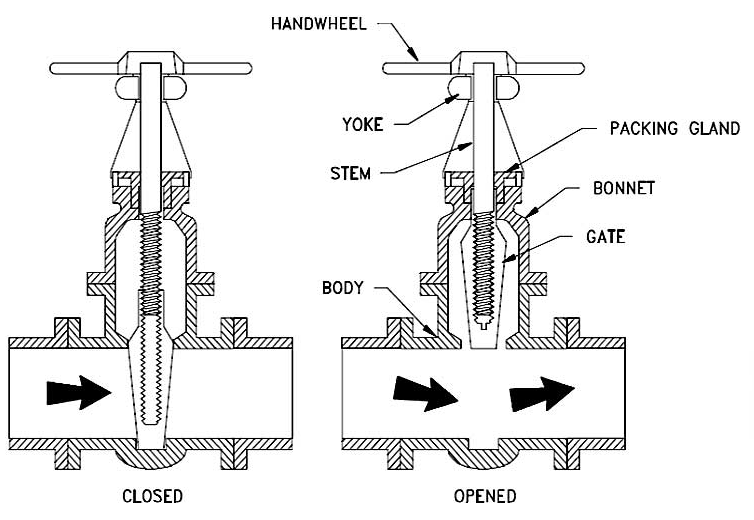

A gate valve operates by turning a handwheel, T-key, or actuator to rotate the stem, which raises or lowers the wedge. When the wedge is fully raised, the valve is open, allowing unobstructed flow. When lowered, the wedge presses against the seat, providing a complete shut-off. The multi-turn operation ensures precise control but is slower than quarter-turn valves like ball valves.

Watch the video above for an animated explanation of gate valve operation.

Gate valves feature a simple yet robust design, with key components ensuring reliable performance:

| Component | Description |

|---|---|

| Body | Houses internal components; typically ductile iron, cast steel, or stainless steel. |

| Wedge | Gate-like disc that seals against the seat; may be solid or flexible. |

| Stem | Connects wedge to handwheel/actuator; rising or non-rising designs. |

| Seat | Sealing surface; metal or resilient (e.g., elastomer) for tight shut-off. |

| Bonnet | Covers the stem and packing; bolted for easy maintenance. |

| Packing | Seals the stem to prevent leaks; often graphite or PTFE. |

| Handwheel/Actuator | Operates the valve; manual or automated (electric, pneumatic). |

Gate valves are classified based on wedge, seat, and stem designs to suit various applications:

| Type | Description | Applications |

|---|---|---|

| Wedge Gate Valve | Wedge-shaped disc with ribs guided by body slots; ensures tight sealing. | Water distribution, oil and gas, high-pressure systems. |

| Parallel Gate Valve | Flat, parallel-faced disc; includes knife gate valves for slurries. | Slurries, wastewater, pulp and paper. |

| Metal-Seated | Metal wedge and seat; durable but may trap solids. | High-temperature, abrasive fluids. |

| Resilient-Seated | Elastomer-coated wedge; tighter seal, handles small solids. | Drinking water, wastewater treatment. |

| Rising Stem | Stem rises during opening; visible position indicator. | Above-ground installations, industrial plants. |

| Non-Rising Stem | Stem threads inside body; compact for buried service. | Underground pipelines, pumping stations. |

Shutting off a gate valve is straightforward but requires careful operation to avoid damage:

Locate the Valve: Identify the gate valve in the pipeline, often marked with a handwheel or T-key.

Determine Closing Direction: Most gate valves close clockwise (marked “cc”); some regions use anti-clockwise (marked “acc”). Check for a direction marker.

Turn the Handwheel: Rotate the handwheel or T-key in the closing direction until resistance is felt, indicating a full shut-off. Avoid over-tightening to prevent damage to the wedge or seat.

Verify Closure: For rising stem valves, the stem will be fully lowered. For non-rising stem valves, use a position indicator or marker to confirm closure.

Note: Gate valves should be fully open or fully closed to avoid vibration and damage from partial operation.

Determining the position of a gate valve depends on its stem type:

Rising Stem: The stem extends outside the valve body when open and retracts when closed, providing a clear visual indicator.

Non-Rising Stem: The stem remains inside the body, making position less obvious. Check for a position indicator or closing direction marker (cc for clockwise, acc for anti-clockwise).

KFTE Valves offers gate valves with optional position indicators for easy monitoring, especially for underground or non-rising stem installations.

Gate valves and ball valves serve different purposes, with gate valves offering unique advantages:

| Feature | Gate Valve | Ball Valve |

|---|---|---|

| Operation | Multi-turn, slower but precise shut-off. | Quarter-turn, fast operation. |

| Flow Resistance | Minimal when fully open; full-bore design. | Low but slightly higher due to ball obstruction. |

| Applications | Isolation in water, oil, gas; not for throttling. | Isolation and throttling in high-pressure systems. |

| Durability | Simple, robust; ideal for infrequent operation. | Compact, durable; suitable for frequent use. |

| Cost | Cost-effective for large diameters. | More expensive for larger sizes. |

When to Choose: Use gate valves for large-diameter pipelines requiring minimal flow resistance and infrequent operation, such as water distribution. Choose ball valves for high-pressure systems needing quick operation or throttling capabilities.

Gate valves and backflow preventers serve distinct functions in fluid systems:

| Feature | Gate Valve | Backflow Preventer |

|---|---|---|

| Purpose | Isolates flow for on/off control. | Prevents reverse flow to protect water supply. |

| Mechanism | Raises/lowers a wedge to stop/allow flow. | Uses check valves or air gaps to block backflow. |

| Applications | Water distribution, industrial pipelines. | Plumbing, irrigation, potable water systems. |

| Flow Direction | Bi-directional shut-off. | Unidirectional to prevent reverse flow. |

When to Choose: Use gate valves for isolating pipeline sections during maintenance or shut-off. Use backflow preventers to ensure water safety by preventing contamination from reverse flow.

Gate valves are not suitable for throttling or flow regulation. Partial opening causes turbulent flow, leading to vibration and cavitation that can damage the wedge and seat, resulting in leaks or reduced sealing performance. For throttling, consider valves like globe or ball valves designed for precise flow control.

Advantages:

Low Flow Resistance: Full-bore design minimizes pressure drop.

Bi-Directional: Effective for flow in either direction.

Durability: Simple design ensures long service life.

Cost-Effective: Economical for large-diameter pipelines.

Pigging Compatibility: Full-port design allows pipeline cleaning.

Disadvantages:

Not for Throttling: Partial operation causes damage.

Slow Operation: Multi-turn mechanism takes time.

Space Requirements: Rising stem valves need vertical clearance.

Solid Trapping: Metal-seated valves may trap solids, affecting sealing.

At KFTE Valves, we offer a wide range of gate valves, including resilient-seated and metal-seated designs, tailored for applications in water, oil, gas, and fire protection systems. Our valves are built with high-quality materials like ductile iron and stainless steel, complying with standards like AWWA C509 and API 600.

Premium Quality: Durable materials for harsh environments.

Custom Solutions: Valves designed for specific needs.

Expert Support: Guidance to select the perfect valve.