Check valves, also known as non-return or one-way valves, are essential components in fluid and gas systems, ensuring flow in one direction while preventing unwanted backflow. At KFTE Valves, we specialize in high-quality check valves designed for reliability and efficiency across industries. This guide explores what check valves are, their types, how they work, their applications, and why they're critical for system performance.

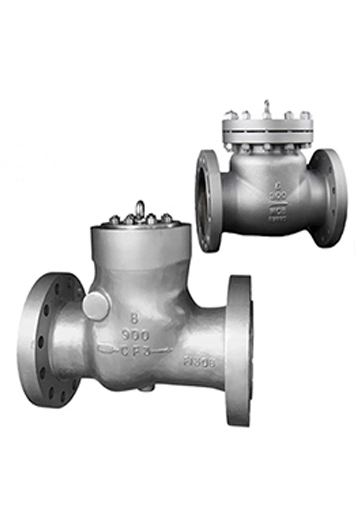

A check valve is a mechanical device that allows fluid or gas to flow in one direction (the free flow direction) while blocking reverse flow (the checked direction). Its primary purpose is to protect systems by preventing backflow, which can cause contamination, equipment damage, or operational inefficiencies. For example, our Cast Check Valve is designed for robust backflow prevention in high-flow applications.

Check valves come in various designs, each suited for specific applications based on flow, pressure, and system requirements. Below are the key types offered by KFTE Valves:

Cast Check Valve: Constructed from cast materials, these valves offer durability and are ideal for general-purpose applications like water and oil pipelines.

Forged Check Valve: Made from forged materials for enhanced strength, perfect for high-pressure and high-temperature systems.

Nozzle Check Valve: Designed for minimal pressure loss and rapid closure, commonly used in compressors and high-velocity systems.

Tilting Disc Check Valve: Features a disc that tilts to open and close, providing quick closure and durability in demanding environments.

Butterfly Swing Check Valve: Combines a butterfly mechanism with swing action, offering low resistance and suitability for large-scale HVAC and water systems.

Choosing the right type depends on your system's needs. Explore our full range of check valves to find the perfect solution.

Unlike gate or ball valves, which require manual or automated operation to control flow, check valves are automatic, responding directly to pressure changes. This distinction makes them ideal for systems where backflow prevention is critical without constant human intervention. For instance, our Forged Check Valve offers superior strength for high-pressure applications compared to traditional gate valves.

| Valve Type | Operation | Backflow Prevention | Common Use |

|---|---|---|---|

| Check Valve | Automatic (pressure-driven) | Yes | Pumps, pipelines, HVAC |

| Gate Valve | Manual/Automated | No | Isolation in pipelines |

| Ball Valve | Manual/Automated | No | Quick shut-off applications |

Check valves operate based on pressure differentials. When fluid or gas pressure in the flow direction exceeds the pressure in the opposite direction, the valve opens, allowing flow. When pressure reverses, the valve closes, preventing backflow. This mechanism is critical in systems like water supply lines, where our Tilting Disc Check Valve ensures reliable operation under varying pressures.

Most check valves include a body, a sealing mechanism (e.g., disc, ball, or poppet), and often a spring to assist closure. The sealing mechanism moves to open or close based on pressure, ensuring minimal leakage. For example, our Cast Check Valve uses a robust disc design to create a tight seal, ideal for general-purpose applications.

Check valves are common in everyday items. For instance, in inflatable devices like air mattresses, a check valve allows air to enter but prevents it from escaping until manually released. Similarly, in dishwashers, check valves prevent dirty water from flowing back into clean water lines, ensuring hygiene.

In industrial settings, check valves are vital for protecting equipment. In oil and gas pipelines, our Nozzle Check Valve minimizes pressure loss while preventing reverse flow. They're also used in HVAC systems, water treatment plants, and chemical processing to maintain system integrity.

Backflow can lead to contamination, pump damage, or system failure. Check valves act as a safeguard, ensuring fluid or gas flows only in the intended direction. For example, a faulty check valve in a water system could allow contaminated water to enter potable supplies, posing health risks. Our Tilting Disc Check Valve is engineered for quick closure to prevent such issues.

By reducing pressure loss and ensuring reliable operation, check valves improve system efficiency. They also enhance safety by preventing overpressure or equipment failure. For high-flow applications, our Butterfly Swing Check Valve offers low resistance and durability, optimizing performance in demanding environments.

What is the Difference Between a Backflow Preventer and a Check Valve?

A backflow preventer is a broader system that may include check valves but often incorporates additional components like pressure relief valves. Check valves are simpler, focusing solely on one-way flow. For complex systems, explore our range of check valves.

What Are the Symptoms of a Bad Check Valve?

Signs of a failing check valve include reverse flow, unusual noises (e.g., rattling), reduced system pressure, or fluid leaks. Regular maintenance and choosing reliable products like KFTE Valves' Forged Check Valve can prevent these issues.

When Should You Use a Check Valve?

Use check valves when you need to prevent backflow, protect equipment, or maintain system pressure. They're essential in applications like pumps, compressors, and pipelines. Browse our check valve catalog to find the right fit for your needs.

For more information or to select the perfect check valve for your system, contact our team at KFTE Valves. Our experts are ready to guide you through choosing the ideal solution for your application.

Wikipedia. (2025). Check Valve. A comprehensive overview of check valve types, functions, and applications. Available at: https://en.wikipedia.org/wiki/Check_valve.

American Society of Mechanical Engineers (ASME). (2023). ASME B16.34: Valves Flanged, Threaded, and Welding End. Industry-standard specifications for valve design, including check valves. Available at: https://www.asme.org/codes-standards/find-codes-standards/b16-34-valves-flanged-threaded-welding-end.

International Organization for Standardization (ISO). (2021). ISO 15761: Steel Gate, Globe, and Check Valves for Sizes DN 100 and Smaller. Technical standards for check valve construction and testing. Available at: https://www.iso.org/standard/77636.html.