Butterfly valves are critical components in fluid control systems, valued for their compact design, quick operation, and versatility across industries. At KFTE Valves, we provide high-quality butterfly valves engineered for durability and performance in applications like water treatment, chemical processing, and HVAC systems. This guide explores what butterfly valves are, their components, types, applications, actuation methods, materials, and how they compare to plug, gate, and ball valves, answering common questions to help you choose the right valve for your needs.

A butterfly valve is a quarter-turn valve that uses a rotating disc, often called the "butterfly," to regulate or isolate fluid flow in pipelines. The disc is mounted on a stem and rotates 90 degrees to either allow (parallel to flow) or block (perpendicular to flow) the passage of fluids. Known for their simplicity and compact design, butterfly valves are ideal for on/off control and, in some cases, basic throttling applications.

Key Features:

Quarter-Turn Operation: 90-degree rotation for fast opening/closing.

Compact and Lightweight: Reduces installation space and costs.

Versatile: Handles liquids, gases, and slurries.

Low Torque: Easy to operate manually or with actuators.

Standards Compliance: Meets API 609, ISO 5752, and other industry standards.

The butterfly valve operates by rotating a disc within the valve body, controlled by a stem connected to an external actuator or handle. In the open position, the disc aligns parallel to the flow, minimizing resistance. In the closed position, the disc is perpendicular, sealing against a seat to stop flow. Partial rotation allows for throttling, though prolonged throttling can cause disc wear, especially in resilient-seated designs.

Watch the video above for an animated explanation of butterfly valve operation.

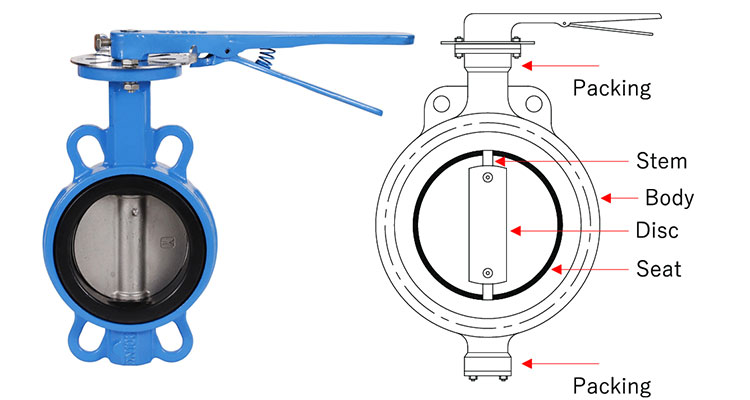

Butterfly valves consist of several key components, each designed for durability and performance:

| Component | Description |

|---|---|

| Valve Body | Houses the disc and connects to the pipeline; available in wafer, lug, or flanged designs. |

| Disc | Rotates to control flow; acts as a gate, similar to a ball in ball valves. |

| Stem | Connects the disc to the actuator; transmits torque for rotation. |

| Seat | Provides a seal between disc and body; made of soft (e.g., EPDM, PTFE) or metal materials. |

| Operating Mechanism | Manual (handwheel, lever) or automated (electric, pneumatic, hydraulic) actuation. |

| Bushings/Bearings | Reduce friction and ensure smooth rotation; often self-lubricating for durability. |

Butterfly valves are widely used across industries due to their efficiency and ability to handle diverse fluids. Key applications include:

Water and Wastewater Treatment: Controlling flow in pipelines, pumping stations, and treatment plants.

Chemical and Oil Industries: Managing corrosive fluids and high-temperature processes.

HVAC Systems: Regulating airflow in heating and cooling systems.

Food and Beverage: Handling hygienic fluids with food-grade seats (e.g., PTFE).

Shipbuilding: Providing durable shut-off in marine environments, including ballast systems.

Fire Protection: Ensuring reliable flow control in sprinkler systems.

Note: While butterfly valves can handle throttling, prolonged use in partially open positions may damage the disc or seat, especially in resilient-seated designs.

Butterfly valves are available in various designs to meet specific application needs:

| Type | Description | Applications |

|---|---|---|

| Zero-Offset Butterfly Valve (Concentric Butterfly Valve) | Stem through disc centerline; resilient seat for sealing. | Low-pressure water, gas, general applications (up to 250 PSI, 400°F). |

| Double-Offset Butterfly Valve | Stem offset from disc and body centerline; reduces seat wear. | Water treatment, HVAC, moderate-pressure systems (up to 1440 PSI, 1200°F). |

| Triple-Offset Butterfly Valve | Conical offset for bubble-tight sealing; minimal friction. | High-pressure steam, oil and gas, corrosive chemicals (up to 1480 PSI, 1200°F). |

| Wafer-Style Butterfly Valve | Compact, sandwiched between flanges; cost-effective. | Universal flow systems, non-isolation applications. |

| Lug-Style Butterfly Valve | Threaded lugs for end-of-line or isolation service. | Dead-end service, maintenance-heavy systems. |

| Double-Flanged Butterfly Valve | Flanges on both sides for robust connection. | Large-diameter, high-stability applications. |

Butterfly valves can be operated manually or automatically, depending on the application:

Manual: Hand levers for small valves or handwheels with gearboxes for larger sizes; self-locking designs prevent back-driving.

Electric: Uses a motor for precise control; ideal for remote or high-precision applications (e.g., 4-20mA control).

Pneumatic: Compressed air actuates the valve; suitable for high-speed, high-cycle systems.

Hydraulic: Uses fluid pressure for high-torque applications, such as high-pressure pipelines.

Many KFTE Valves butterfly valves feature ISO 5211 mounting pads for easy actuator integration, ensuring compatibility with industry-standard automation systems.

The performance, durability, and suitability of butterfly valves depend heavily on their construction materials. The valve body, disc, stem, and seat must be tough and rigid to withstand fluid pressures and environmental conditions. Below is a detailed overview of common materials used for butterfly valve components, including their properties and applications:

Metal Butterfly Valves

Metal materials are chosen for their strength, corrosion resistance, and ability to handle high temperatures and pressures.

| Material | Properties | Applications | Temperature/Pressure Ratings |

|---|---|---|---|

| Stainless Steel | High chromium (10.5-30%), nickel, and molybdenum; exceptional strength, corrosion resistance via chromium oxide layer, self-regenerating; molybdenum prevents pitting. | Acidic/corrosive fluids, cryogenic processes (austenitic grades), high-pressure systems (duplex grades). | Wide temperature range; 316SS preferred for high performance. |

| Carbon Steel | Up to 2.5% carbon; good mechanical properties, cost-effective; ASTM A216 WCB for high temps, LCC for low temps. | Non-corrosive fluids, general applications; not suitable for corrosive environments. | WCB: high temps; LCC: low temps; up to 1500 PSI. |

| Hastelloy | Nickel-chromium-molybdenum alloy; high strength, corrosion resistance to acids (nitric, hydrochloric, sulfuric), cracking resistance. | Oil and gas, power generation, corrosive/high-pressure environments. | Moderate to high temps; high pressures. |

| Brass | Copper-zinc alloy; tough, durable, corrosion/biofouling-resistant, antimicrobial; not suitable for high-chlorine water (dezincification risk). | Water purification, wastewater treatment, food/pharmaceutical industries. | High temps; moderate pressures. |

| Nickel Alloys | Superior corrosion resistance, high-temp performance; denser and costlier than stainless steel. | Extremely corrosive environments, high-temp applications. | High temps; high pressures. |

| Titanium Alloys | High strength-to-weight ratio, corrosion/biofouling-resistant, non-toxic; expensive. | Seawater, water treatment, offshore piping. | Moderate temps; high pressures. |

| Nickel Aluminum Bronze | 10% aluminum, 5% nickel, 5% iron; corrosion/antimicrobial/biofouling-resistant. | Seawater, offshore piping, water/wastewater treatment. | Moderate temps; high pressures. |

Plastic Butterfly Valves

Plastic valves are lightweight and cost-effective but have lower temperature tolerances compared to metals.

| Material | Properties | Applications | Temperature/Pressure Ratings |

|---|---|---|---|

| Polyvinyl Chloride (PVC) | Strong, rigid, corrosion-resistant; hygienic, easy to clean; unsuitable for hydrocarbons/aromatic compounds. | Food/beverage processing, water supply, irrigation, wastewater treatment. | Up to 60°C; 150 PSI. |

| Chlorinated Polyvinyl Chloride (CPVC) | Higher chlorine content than PVC; flexible, higher temp tolerance; more expensive. | Hot/cold potable water, industrial liquids, swimming pools. | Up to 93.3°C; 150 PSI. |

| Polypropylene (PP) | Strong, corrosion/UV/biofouling-resistant; selective compatibility with organic solvents. | Aquaculture, wastewater treatment, chemical manufacturing. | Up to 80°C; moderate pressures. |

| Glass Fiber-Reinforced Polypropylene (GFPP) | Enhanced rigidity, tensile/flexural strength with glass fibers; corrosion-resistant. | Heavy-duty chemical, wastewater applications. | Up to 80°C; moderate pressures. |

| Polyvinylidene Fluoride (PVDF) | Lightweight, abrasion/corrosion-resistant; compatible with alcohols, hydrocarbons, halogenated solvents. | High-purity chemical manufacturing, suspended solids. | Up to 120°C; moderate pressures. |

| Acrylonitrile Butadiene Styrene (ABS) | Strong, rigid, impact-resistant; cost-effective; used for discs with PP/PVC/GFPP housings. | Water treatment, general applications. | Up to 60°C; moderate pressures. |

Butterfly Valve Seats

Seats determine the valve's sealing performance and temperature/pressure ratings. They are categorized as soft or metal seats.

Soft Seats

| Material | Properties | Applications | Temperature Range |

|---|---|---|---|

| Polytetrafluoroethylene (PTFE) | Low friction, chemical/heat-resistant, non-toxic; ideal for food/pharma. | Food, pharmaceutical, chemical processing. | -100°F to 450°F. |

| Reinforced PTFE (RTFE) | PTFE with 15% glass fiber; enhanced wear/compressive strength; not for hydrofluoric acid/caustic soda. | Chemical, general applications. | -320°F to 450°F. |

| Ethylene-Propylene Diene Monomer (EPDM) | Elastic, abrasion-resistant; handles acids, alcohols, chlorinated water; not for petroleum solvents. | Water treatment, chemical processing. | -20°F to 230°F. |

| Buna-N (Nitrile Rubber) | Durable, wear-resistant; suitable for gases, water, fuels; not for ketones/ozone. | Water, fuel, alcohol handling. | -35°F to 250°F. |

| Viton (FKM) | Chemical-resistant elastomer; less effective for steam/water. | Chemical processing, fuel systems. | -20°F to 400°F. |

| Neoprene | Flexible, resistant to greases/oils; flame-resistant; not for strong oxidizers. | Refrigerants, pulp/paper manufacturing. | -35°F to 225°F. |

Metal Seats

| Material | Properties | Applications | Temperature Range |

|---|---|---|---|

| Inconel | Nickel-chromium-molybdenum alloy; corrosion/oxidation-resistant; high strength. | High-pressure steam, power generation. | Up to 900°F. |

| Stainless Steel | Cost-effective, corrosion-resistant; strong performance. | High-temp, corrosive applications. | Wide range, varies by grade. |

| Stellite | Cobalt-chromium-tungsten alloy; corrosion-resistant, customizable durability. | High-wear, high-temp applications. | High temps, varies by grade. |

| Nitrided Metals | Hardened via nitrogen diffusion; enhanced wear/corrosion resistance. | High-pressure, abrasive environments. | High temps, varies by base metal. |

KFTE Valves offers butterfly valves in a range of materials tailored to your application, ensuring compliance with standards like API 609 and NSF/ANSI 61 for quality and safety.

Both butterfly and plug valves are quarter-turn valves, but their designs and applications differ:

| Feature | Butterfly Valve | Plug Valve |

|---|---|---|

| Design | Rotating disc in flow path. | Cylindrical/conical plug with passageway. |

| Size and Weight | Compact, lightweight; ideal for large diameters. | Heavier, more robust design. |

| Flow Characteristics | Linear flow; limited throttling due to disc wear. | Equal percentage flow; better for throttling. |

| Sealing | Tight shutoff, especially with metal seats. | Excellent sealing in low-pressure systems. |

| Applications | Water, HVAC, large pipelines. | Slurries, low-pressure, corrosive fluids. |

| Cost | Cost-effective for large sizes (DN 50+). | Less expensive for manual operation. |

When to Choose: Butterfly valves excel in large-diameter, cost-sensitive applications like water treatment. Plug valves are better for slurries and low-pressure systems requiring robust sealing.

Butterfly and gate valves serve distinct roles in flow control:

| Feature | Butterfly Valve | Gate Valve |

|---|---|---|

| Operation | Quarter-turn, fast operation. | Multi-turn, slower operation. |

| Design | Rotating disc for flow control. | Sliding gate for full isolation. |

| Applications | Water, slurries, HVAC, on/off control. | High-pressure isolation, minimal throttling. |

| Flow Resistance | Moderate due to disc in flow path. | Low when fully open. |

| Size and Weight | Compact, lightweight. | Larger, heavier; needs more space. |

When to Choose: Butterfly valves are ideal for quick operation and space-constrained systems. Gate valves suit high-pressure isolation where throttling is not needed.

Butterfly valves offer distinct advantages over ball valves:

Cost-Effectiveness: Cheaper, especially for larger diameters (DN 50+).

Compact Design: Slim profile reduces installation space and weight.

Low Torque: Easier to operate with smaller actuators.

Large-Diameter Suitability: Ideal for pipelines up to DN 2500.

Limitations: Butterfly valves are less suited for high-pressure applications and cannot be pigged due to the disc’s presence. Ball valves excel in high-pressure, small-diameter systems with precise control needs.

When to Choose: Use butterfly valves for cost-effective, large-scale applications with moderate pressure. Choose ball valves for high-pressure systems requiring minimal pressure drop.

Advantages:

Low Pressure Drop: Minimizes pumping system energy loss.

Quick Operation: 90-degree rotation for fast on/off control.

Compact Design: Saves space and reduces installation costs.

Cost-Effective: Less material and simpler manufacturing than gate or globe valves.

Versatility: Handles large flows, slurries, and various temperatures/pressures.

Disadvantages:

Limited Throttling: Prolonged throttling can damage disc/seat, especially in resilient-seated valves.

Sealing at High Pressures: Less effective than ball valves in high-pressure applications.

Cavitation Risk: Potential for cavitation or choking in high-flow conditions.

Not Full-Bore: Disc in flow path prevents pigging for cleaning.

At KFTE Valves, we offer a comprehensive range of butterfly valves, from zero-offset to triple-offset designs, built to meet industry standards like API 609, ISO 5752, and NSF/ANSI 61. Our valves are crafted with premium materials like stainless steel, Hastelloy, and PTFE to ensure durability in demanding environments.

Why KFTE?

High-Quality Materials: Designed for corrosion resistance and longevity.

Custom Solutions: Tailored valves for specific industry needs.

Expert Support: Guidance to select the ideal valve for your application.

Contact Us Today to discover our butterfly valve solutions!