A butterfly valve is a quarter-turn valve that controls or isolates flow using a rotating disc. Among its various designs, the eccentric butterfly valve represents a significant engineering advancement. It overcomes key limitations of traditional concentric butterfly valves—where the disc stem passes through the disc centerline—by employing an offset stem. This crucial modification dramatically improves sealing performance, reduces wear, and extends service life, making it suitable for more demanding industrial applications.

The defining feature is the offset placement of the valve stem relative to the disc and seat. There are three main configurations, each adding a layer of sophistication:

Single Eccentric (Single-Offset): The stem is located behind the centerline of the disc and seat. This simple offset allows the disc to lift from the seat almost immediately upon opening, minimizing initial friction.

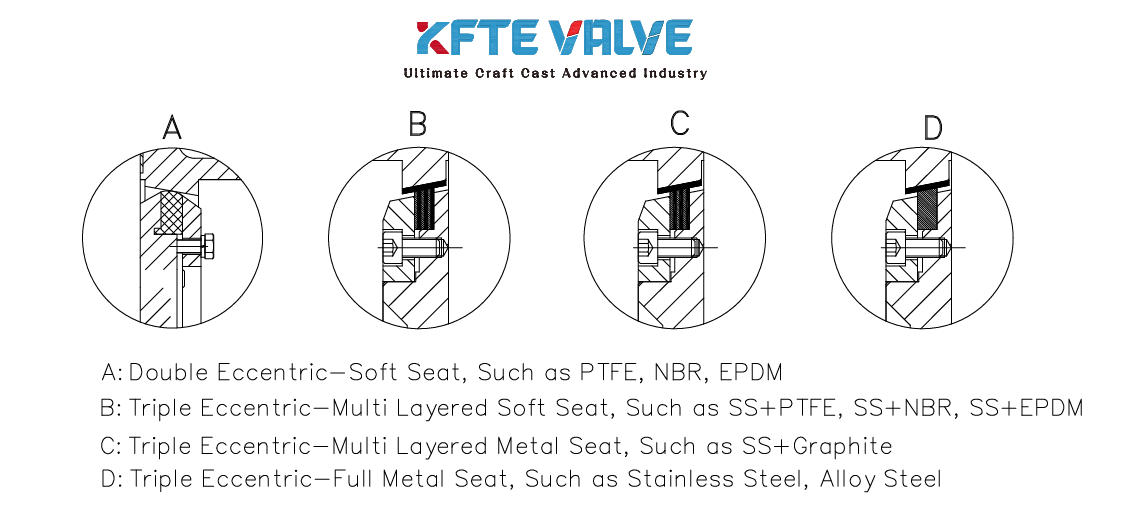

Double Eccentric (Double-Offset): This design incorporates two offsets. First, the stem is behind the seat center. Second, the stem axis is offset from the pipe/valve centerline. This creates a cam-like motion. As the valve opens, the disc moves completely away from the seat in a sweeping motion, virtually eliminating sliding contact and associated wear throughout 90% of its operation.

Triple Eccentric (Triple-Offset): The most advanced design adds a third offset: the conical angle of the seating surface. This geometry ensures that the metal seats only make contact at the point of final closure. It enables bubble-tight shut-off with metal seats, making the valve suitable for extreme temperatures and pressures.

The eccentric motion directly enables more robust and reliable sealing mechanisms, moving away from constant friction-based sealing.

Soft-Seated Seals (Typical for Double Eccentric): The seat is made from resilient materials like EPDM, Nitrile, or PTFE. The eccentric action compresses the seat against the disc periphery only at complete closure, achieving excellent tightness for general services.

Metal-Seated Seals (Hallmark of Triple Eccentric): The seat and disc edge are precision-machined from metals (e.g., stainless steel) or use a layered composite (metal carrier with a resilient insert). The conical, triple-offset geometry creates a wedging effect for a tight seal without friction, ideal for corrosive, high-temperature, or abrasive media.

The eccentric design confers several critical benefits over concentric butterfly valves:

Reduced Wear & Longer Life: The elimination of constant sliding friction between disc and seat drastically reduces wear, lowering maintenance costs and extending valve life.

Superior Sealing & Bubble-Tight Shut-Off: The cam-action closure allows for higher sealing forces without excessive torque, enabling reliable isolation, even for gases and vacuum services.

Lower Operating Torque: With friction minimized, less torque is required to operate the valve, allowing for smaller, more cost-effective actuators.

High Performance Range: Particularly triple-eccentric designs can handle a wide spectrum of pressures, temperatures (cryogenic to very high heat), and aggressive media.

Reliable, Maintenance-Free Operation: The robust design with minimal wear components ensures consistent performance over long periods with minimal intervention.

Eccentric butterfly valves offer flexible installation options:

Wafer Style: The most compact and economical. The valve fits between two pipe flanges, secured by bolts running through the entire assembly. It is not suitable for end-of-line isolation.

Lug Style: The valve body has threaded inserts (lugs) on both sides. Each pipe flange can be bolted independently to these lugs, allowing the valve to be installed at the end of a pipeline for isolation and supporting downstream pipe removal.

Double Flanged (Flanged Ends): The valve features integral flanges at both ends, matching standard pipe flanges. This provides the strongest, most leak-resistant connection for high-integrity services.

Welded Ends: For permanent, high-pressure, or critical installations, valves can be supplied with butt-weld or socket-weld ends to be welded directly into the pipeline.

Thanks to their durability and sealing performance, eccentric butterfly valves are indispensable across numerous industries:

Water & Wastewater: Pump isolation, filter systems, clean/dirty water mains, and treatment plants.

Oil, Gas & Petrochemicals: Process water, cooling systems, hydrocarbon handling (especially triple-eccentric with metal seats), and offshore platforms.

Power Generation: Cooling water circuits, fuel oil systems, and flue gas desulfurization (FGD) units.

HVAC: Isolation and control in large-scale heating and chilled water distribution networks.

Marine & Shipbuilding: Seawater cooling, ballast, and bilge systems due to compact design and corrosion resistance.

Chemical & Pharmaceutical: Handling of various process fluids where reliable isolation is critical.

The eccentric butterfly valve is a sophisticated evolution of a simple concept. By strategically offsetting the stem, it transforms into a high-performance, reliable, and versatile flow control solution. Its ability to minimize wear, ensure tight sealing, and adapt to various connection types and harsh service conditions makes it a preferred choice for engineers across a vast range of modern industrial applications.