A metal-sealed butterfly valve, also known as a hard-sealed butterfly valve, is a critical flow control device designed for demanding industrial applications. Its core distinguishing feature is a sealing mechanism where both the disc and the seat are made of metal, creating a robust metal-to-metal interface.

Originally used for basic on/off and throttling services in low-pressure systems, advancements in design, particularly the development of eccentric structures, have significantly expanded their capabilities into high-temperature and high-pressure services.

The performance of modern metal-sealed butterfly valves is largely defined by their sealing geometry and material technology.

Eccentric Design: The transition from a simple centerline design to advanced eccentric designs has been pivotal in enhancing butterfly valve life and sealing performance. The primary designs include:

Double Eccentric: The shaft is both behind and to the side of the seal's center, minimizing friction between the seat and disc.

Triple Eccentric: This advanced design incorporates three distinct offsets (axial, radial, and conical angle eccentricity). It ensures that the sealing surfaces completely disengage during the opening cycle, eliminating sliding friction and wear.

Sealing Structure Innovation: Traditional multi-layer laminated seals could be prone to erosion. Modern improvements focus on integral or specially designed metal sealing rings. State-of-the-art designs aim for bidirectional zero leakage, capable of withstanding pressure from both flow directions.

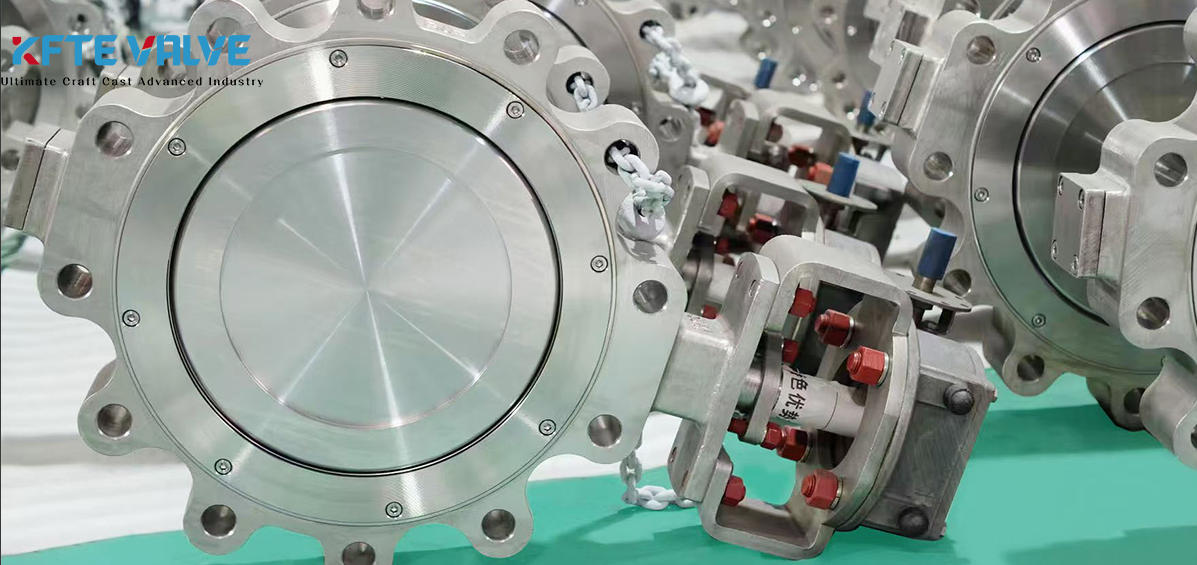

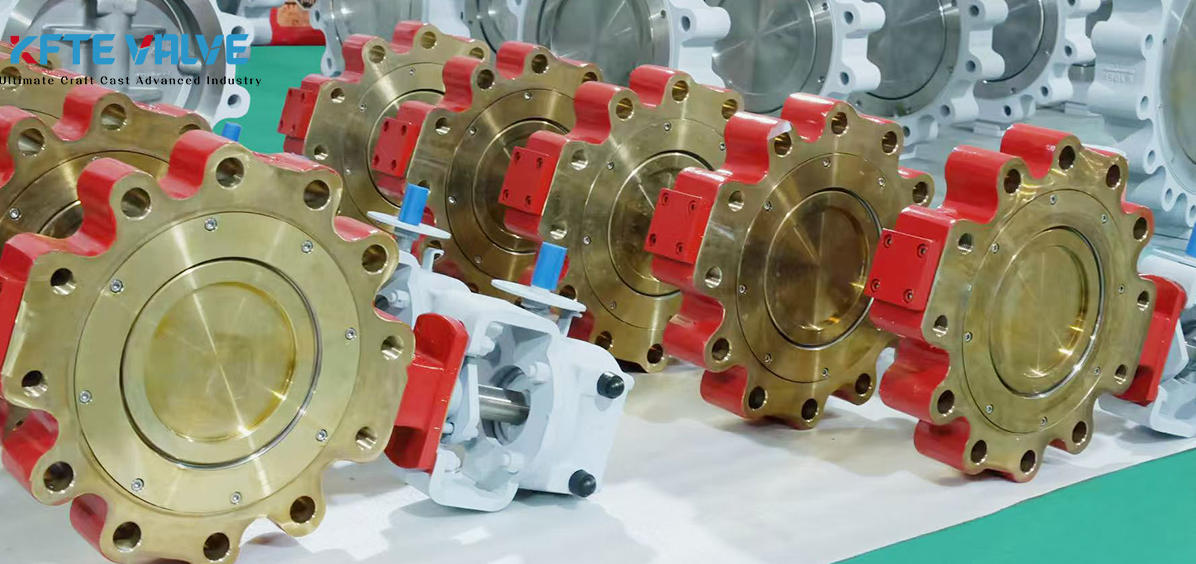

Material and Construction: Sealing surfaces are often overlaid with wear-resistant, temperature-resistant, and corrosion-resistant alloys (e.g., stainless steel, Stellite) to suit harsh media. The valve body can be configured in wafer or flanged styles, with the wafer type being notably compact and lightweight.

Exceptional Temperature and Pressure Resistance

High-Temperature Resistance: Both the seat and disc sealing surfaces are made of special metal materials (e.g., stainless steel, Stellite, hard alloys), capable of withstanding temperatures from 425°C to over 600°C.

High-Pressure Resistance: The strength and hardness of the metal seal structure make them suitable for pressure classes up to Class 600 (PN100) and even higher, ensuring reliable performance in medium and high-pressure pipeline systems.

Superior Wear and Erosion Resistance

The metal hard-sealed surfaces offer extremely strong resistance to solid particles, dust, ash, slurry, crystalline substances, etc., within the medium. In industries like coal chemical, powder conveying, metallurgy, and mineral slurry processing, where media contain abrasive particles, their service life far surpasses that of soft-sealed valves.

Excellent Corrosion Resistance

Materials and surface treatments (e.g., weld overlay of corrosion-resistant alloys, ceramic coating, nitriding) can be selected based on media characteristics. Suitable for corrosive environments such as acid/alkali media, organic solvents, and high-temperature steam, offering a very broad application range.

Inherent Fire Safety

In the extreme event of a fire, it can maintain a degree of sealing integrity, helping to effectively prevent fire propagation. This complies with stringent fire safety standards like API 607/API 6FA, making them essential for high-safety applications such as petrochemical and oil/gas pipelines.

True Bidirectional Sealing

Triple-offset metal-seated butterfly valves, due to their geometric design, can achieve reliable zero-leakage or micro-leakage sealing.

Given their robust design, metal-sealed butterfly valves are indispensable in industries with extreme process conditions:

Power Generation: Used in critical cooling water systems and high-temperature steam lines.

Oil, Gas, and Petrochemical: Handling crude oil, process gases, and corrosive chemicals in refineries and chemical plants.

Metallurgy & Mining: Controlling abrasive slurries, air, and gas in smelting and processing facilities. They are a preferred choice in sulfuric acid plants for gas and process lines.

High-Temperature Utilities: Managing steam, hot water, and other high-temperature fluids where soft seals would fail.

The metal-sealed butterfly valve has evolved from a simple flow regulator into a high-performance engineering solution. Its continuous innovation in eccentric design and sealing technology ensures reliable, long-term service in the most challenging industrial environments, offering a compelling alternative where temperature, pressure, or media aggressiveness rule out the use of soft-sealed valves.