A full welded ball valve is a valve designed for use in pipeline systems. Unlike traditional ball valves, its main components are welded together without any threads or flanges. This design minimizes potential leaks and provides the valve with exceptional structural strength.

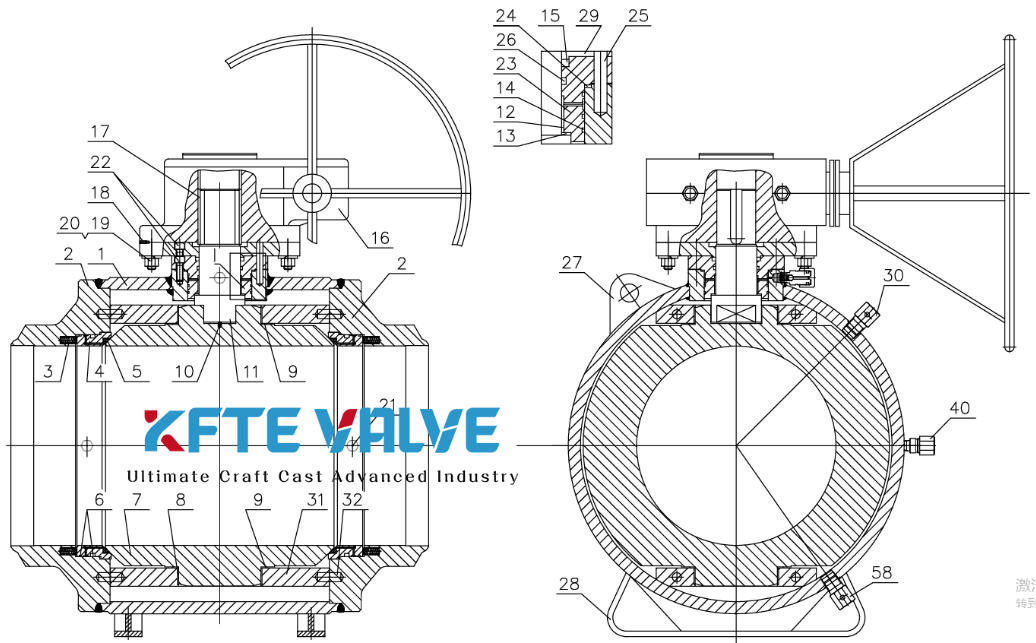

A full welded ball valve typically consists of a ball, stem, seat, seal, and bonnet, with the ball being the most critical component. The ball is typically made of stainless steel or carbon steel and welded to the pipeline. The valve stem drives the internal ball to rotate, opening and closing the pipeline.

The fully welded design of a full welded ball valve offers unparalleled advantages over traditional valves, with its most significant advantage being its reliable sealing performance. The integrally welded body replaces bolted connections, eliminating leak-prone components like flanges and bolts. This eliminates any gaps between the ball and the pipeline, eliminating the possibility of leakage from the valve body itself and providing an extremely high level of safety. The full welded ball valve's body is a completely welded structure, eliminating the weak link of bolts in flange connections. It can withstand extremely high pipe stress, ground subsidence, and internal and external pressures, making it particularly suitable for high-pressure applications. Furthermore, its welded construction effectively resists vibration and provides excellent overall rigidity. Combined with a high-quality anti-corrosion coating, it boasts an extremely long service life of decades in harsh environments, such as direct underground burial and submarine installations. Compared to flanged ball valves of the same specification, fully welded construction is typically more compact and lighter, making it advantageous in space-constrained installations.

Full welded ball valves feature a stem anti-blowout mechanism, which prevents the stem from ejecting in the event of packing damage through a lower boss design. A built-in anti-static device dissipates static electricity generated by friction between the ball and the valve seat, preventing sparks. The fireproof structure complies with international standards such as API 607. In the event of a fire, if the non-metallic seal burns out, a metal ring, using spring force, creates an emergency seal with the ball.

Full welded ball valves, with their advantages of sealing reliability and compact structure, are widely used in various long-distance pipelines and critical facilities. In long-distance pipelines like the West-East Gas Pipeline, full welded ball valves are suitable for gas output trunk lines, branch lines, and oil pipelines. Their high-pressure and leak-proof properties effectively reduce medium loss and safety risks. In the centralized heating and thermal power industries, full welded ball valves are suitable for large-scale heating equipment output pipelines, thermal trunk lines, and heat exchanger circuits. Their direct-buried installation feature allows for pipeline laying beneath dense urban roads, minimizing the impact of construction on traffic. In the power industry, fully welded ball valves are primarily used in boiler feedwater systems and steam pipelines. Their low fluid resistance and high-temperature resistance improve system efficiency and extend equipment life. In the chemical industry, fully welded ball valves are widely used in pipelines transporting various corrosive media and toxic gases. Their corrosion and wear resistance ensure safe pipeline operation. In addition to the aforementioned applications, fully welded ball valves are also widely used in the pharmaceutical, food, and papermaking industries, where their high efficiency, reliable sealing performance, and corrosion resistance are fully utilized.

Continuous development of quality is one of the core values of KFTE. KFTE Valves are designed, manufactured and tested in accordance with API, ASME, ISO and other applicable standards. Original certificates of raw material are recorded in order to guarantee traceability for each material component. Our quality system strictly monitors all stages of manufacturing processes to assure the valves produced by KFTE meet the highest industry standards.

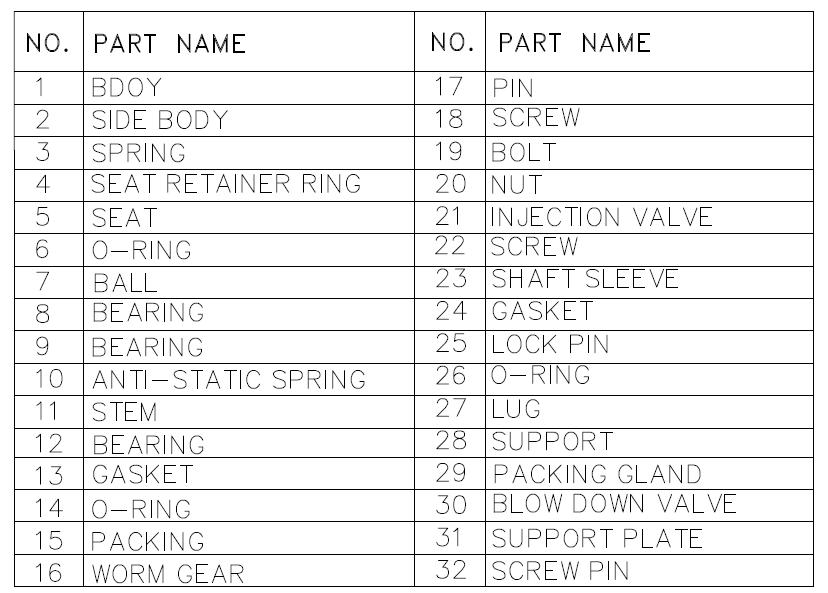

Applicable Standards: | |

Basic Design: | API 6D, ASME B16.34 |

Face to Face: | ASME B16.10, API 6D |

Flange End: | ASME B16.5 (up to 24") |

ASME B16.47 series A (26" and above) | |

EN1092-1 | |

Butt Welded End: | ASME B16.25 |

Test and Inspection: | API 598 |

Fire-safe Test: | API 6FA or API 607 |

Fugitive Emission Test: | ISO 15848-2 |

Type Testing for FE: | ISO 15848-1 |

Other: | NACE MR01-75, MR 0103 |

Design Specifications: | |

Size Range: | 2" ~ 48" DN50 ~ DN1200 |

Pressure Range: | 150LB ~ 1500LB PN10~PN250 |

End Connection: | Flanged end / Butt welding end |

Bore: | Full bore |

Operation: | Manual operation, Actuated operation |

Material: | Carbon steel, Stainless steel |

Low Temperature Carbon steel | |

High Temperature Alloy Steel | |

Duplex Stainless steel | |

Seal: | PTFE, RPTFE, Nylon, Devlon, PEEK |

O-Ring: | Viton, NBR, HNBR, AFLAS |