In the lifeblood of modern industry—the pipeline system—valves play the crucial role of "joints," controlling the flow, shut-off, and distribution of media. Among them, ball valves are one of the most widely used valve types due to their excellent sealing, quick operation, and low flow resistance. Within the ball valve family, Top-Entry, Side-Entry, and Full Welded ball valves occupy distinct core application areas due to their unique designs. Understanding the differences between them is key to proper selection, ensuring system safety and economic operation.

Top-Entry Ball Valve

This design prioritizes maintenance convenience.

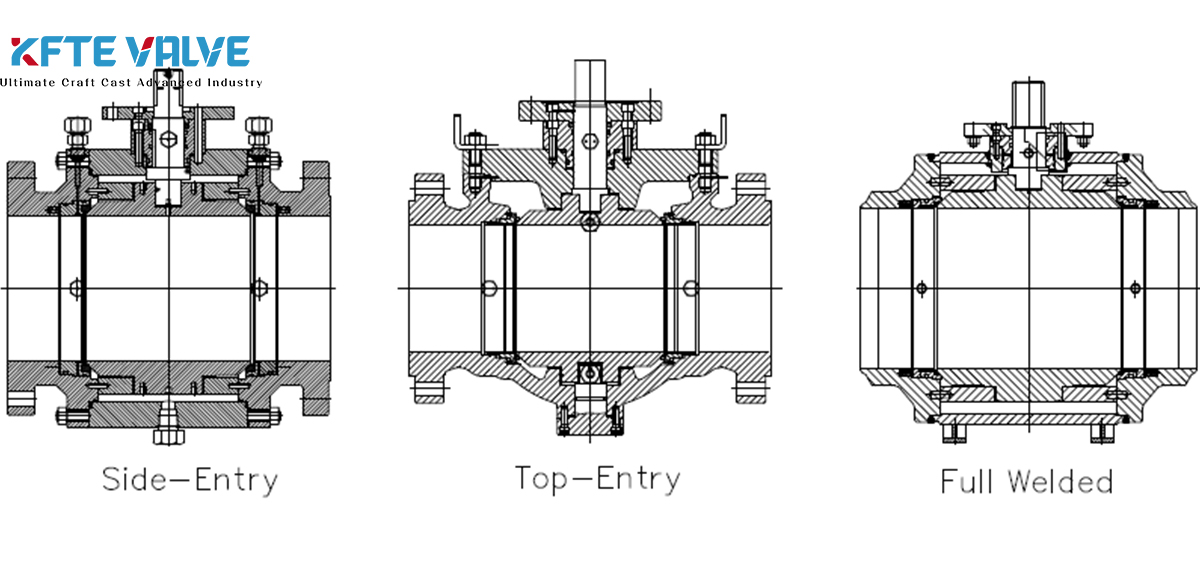

Structural Principle: It features a large, removable bonnet at the top. All internal core components (ball, stem, seats) are pre-assembled into a "cartridge" and loaded into the valve body as a single unit from the top opening. The bonnet is then bolted shut.

Advantages & Limitations:The key advantage is "In-line Maintenance". If the valve fails, technicians simply unbolt the top bonnet to lift out the entire internal cartridge for inspection or replacement, while the valve body remains welded or fixed to the pipeline. The structure is more complex than side-entry types, usually resulting in larger dimensions, heavier weight, and a higher initial cost.

Side-Entry Ball Valve

This is the most traditional and economical ball valve structure.

Structural Principle: The body is typically made of two (or more) halves joined together around the perimeter by bolted flanges. All internal parts are assembled through the side split.

Advantages & Limitations:Simple and intuitive design, with mature manufacturing processes, making it the most cost-competitive and widely used type. Its main limitation is that the entire valve must be removed from the pipeline for any maintenance. This requires breaking both pipeline connections, which is inconvenient for welded lines or tight spaces. Additionally, the gasket seal between the body halves is a potential external leakage point.

Fully Welded Ball Valve

This design aims for ultimate sealing integrity and structural reliability.

Structural Principle: Instead of bolted connections, the body is made from forged or cast parts joined into an inseparable unit via full penetration welding. This eliminates all external flanges and bolts, creating a permanent, leak-proof connection to the pipeline.

Advantages & Limitations:Absolutely Reliable External Seal: With no external leak paths, it is ideal for dangerous/expensive media (e.g., natural gas, hot oil) and directly buried pipelines. Very High Structural Strength: The welded monolithic body better resists pipeline stress, ground settlement, and seismic forces. The trade-off is near-zero reparability. Internal damage typically cannot be fixed on-site; the valve must be cut out and replaced entirely, leading to high maintenance costs.

Comparison Dimension | Top-Entry Ball Valve | Side-Entry Ball Valve | Full Welded Ball Valve |

Core Structure | Features a removable bonnet (top cover). Internal components are assembled as a cartridge and loaded from the top. | The body consists of two or more pieces joined by bolted side flanges, assembled from the side. | The body is a single, welded structure with no external bolts, forming a permanent seal. |

Core Advantage | In-line Maintenance: Repairs can be made without removing the valve from the pipeline, minimizing downtime. | Simple & Economical: Mature design, low cost, easy to disassemble completely for maintenance. | Zero External Leakage, High Reliability: No external sealing points, high strength, long service life (often 15+ years), ideal for buried/severe environments. |

Main Disadvantage | Relatively complex structure, typically larger and heavier, with a higher initial cost. | Cannot be repaired in-line; must be removed entirely for maintenance. Potential leakage at bolted connections. | Essentially Non-repairable: Internal damage usually requires cutting out and replacing the entire valve, resulting in very high repair costs. |

Internal Design Features | Often uses floating or trunnion-mounted ball design, frequently with spring-loaded mechanisms for seal pre-load or wear compensation. | The most common and straightforward design. Internal ball and seats are easily accessible. | Internal body primarily comes in Cylindrical, Conical, or Spherical types, each with different performance focuses for pressure handling and manufacturing. |

Here is a detailed introduction to the application scenarios of the three ball valve designs, based on their core characteristics.

Top-Entry Ball Valve: For Critical, Uninterrupted Service

This design is the go-to solution for processes where scheduled downtime is extremely costly or unacceptable.

Primary Industries: Oil & gas production/refining, petrochemical plants, large-scale chemical processing, power generation.

Typical Applications:

Main Process Lines: Installed in the heart of continuous production units (e.g., refinery crude distillation, catalytic cracking units).

Isolation Valves for Major Equipment: Used for pumps, compressors, reactors, and large heat exchangers, allowing safe isolation for maintenance without shutting down the entire loop.

Severe Service: Handling corrosive, toxic, or abrasive media where reliable shut-off is critical for safety.

Why It's Chosen: The sole reason is In-line Maintainability. When a seal fails, the internal cartridge can be replaced in a matter of hours with the valve body still in the line, avoiding a days-long, multi-million-dollar plant shutdown.

Side-Entry Ball Valve: The General-Purpose Workhorse

This is the most common and economical choice for the vast majority of standard industrial applications.

Primary Industries: Water & wastewater treatment, HVAC, general manufacturing, food & beverage, pharmaceuticals, building services, lower-pressure chemical plants.

Typical Applications:

Utility Services: Cooling water, air, steam, and other auxiliary lines.

Isolation & On/Off Control: In systems with regular planned shutdowns for maintenance.

Applications with Frequent Valve Replacement: Where cost-effective removal and full replacement is part of the maintenance plan.

Why It's Chosen: Cost-Effectiveness and Simplicity. It offers reliable performance for standard pressures and temperatures at the lowest initial investment. Its easy disassembly also allows for complete inspection and part replacement during overhaul periods.

Full Welded Ball Valve: For Permanent, Leak-Free Integrity

This design is specified for applications demanding maximum safety, zero external leakage, and exceptional durability with minimal maintenance.

Primary Industries: Pipeline transmission (onshore/offshore), district heating/cooling networks, liquefied natural gas (LNG) facilities, nuclear power (secondary systems), and critical city gas networks.

Typical Applications:

Buried/Underground Pipelines: For natural gas distribution, hot water/steam supply, and crude oil/product transmission. The welded body resists soil corrosion and stresses.

Pipeline Sectionalizing Valves: Installed along long-distance transmission lines (e.g., cross-country gas pipelines) for emergency isolation.

Subsea/Offshore Applications: Where reliability is paramount and access for repair is prohibitively expensive.

High-Pressure, Hazardous Media Lines: In compressor stations, gas storage facilities, or process areas with flammable/ toxic fluids.

Top-entry, side-entry, and fully welded ball valves are not merely a matter of simple better-or-worse comparison. They are precise solutions engineered to meet distinct challenges. Like different wrenches in an industrial toolbox, each has its irreplaceable purpose. In engineering projects, by deeply understanding their underlying design philosophy and conducting a comprehensive evaluation that considers specific process requirements, safety standards, maintenance strategies, and total lifecycle cost, one can select the most suitable and reliable "precision joint" for the pipeline system—the "industrial heart"—ensuring the safe and efficient flow of energy and materials

This is the first one.