In the vast field of valve manufacturing, there are numerous types of valves, each with its own distinct functions. From common gate valves and butterfly valves to specialized globe valves, each valve type has its own unique structural features and application scenarios. The jacketed plug valve, a novel variant of the conventional plug valve, is used in processes with stringent temperature requirements to heat the conveyed medium to prevent crystallization.

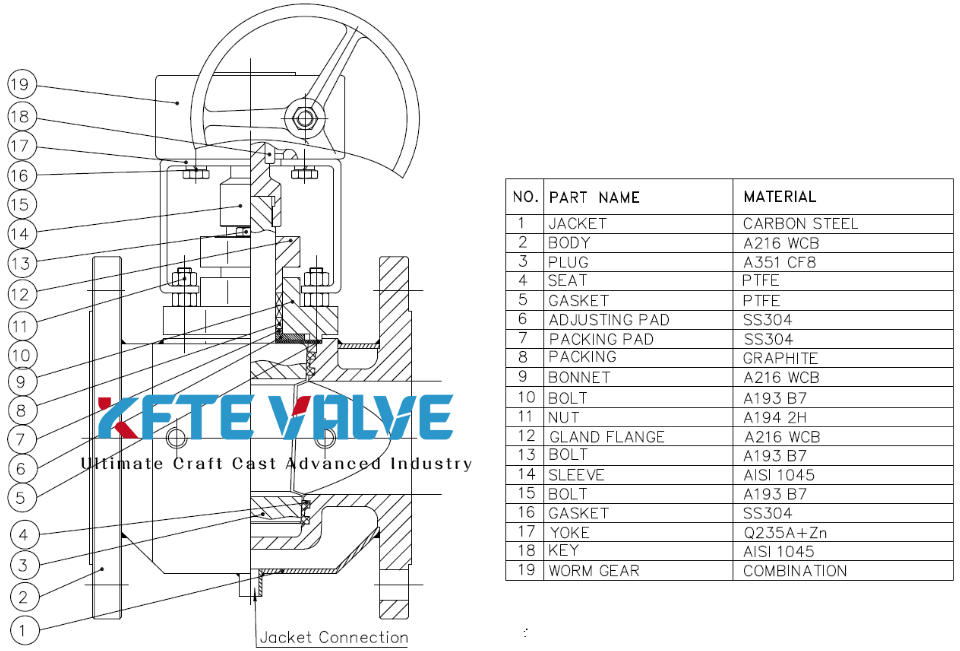

To understand the jacketed plug valve, it's important to first understand its key difference from other common valves: its jacket structure. Conventional valves typically have a single-layer structure, primarily functioning to contain liquid and control flow and on-off control. Jacketed plug valves, on the other hand, incorporate an additional "shell" over the valve body of a conventional plug valve, isolating the jacket from the internal fluid passages. Heat or cooling sources can be introduced into the jacket to insulate or cool the primary medium flowing through the valve body.

(Jacketed Plug Valves are widely used in oilfield extraction, transportation, and refining equipment to handle high-viscosity crude oil or media containing suspended particles.)

The unique structure of the jacketed plug valve offers several distinct advantages. First, its double-layer structure makes it less susceptible to fluid leakage. The unique structure of the jacket layer also provides excellent insulation and cooling properties. Continuously feeding heat medium into the jacket layer prevents certain high-viscosity liquids from solidifying due to temperature drops, thus preventing valve clogging. Conversely, the refrigerant can also cool certain specialized materials. Therefore, jacketed plug valves can be used in high-temperature and high-pressure environments, enjoying a wide range of industrial applications. Conventional valves are prone to clogging in environments prone to solidification, but jacketed plug valves fundamentally address this issue, significantly improving valve safety and reliability. Their low wear also reduces maintenance costs. In addition to the unique advantages of the jacketed structure, jacketed plug valves also inherit various advantages of plug valves. First, the plug valve's passage area is essentially the same as the pipe diameter, minimizing fluid flow resistance and improving flow efficiency. The plug valve can be fully opened or closed with a 90° rotation, making operation more convenient and quicker. This type of valve features a simple and compact design and is relatively easy to install. Of course, due to the double-layer structure of a jacketed plug valve, its manufacturing process is more difficult and more expensive than that of a conventional valve of the same specification. Furthermore, if the process medium does not have specific temperature requirements, using a jacketed plug valve would be wasteful.

(In the chemical industry, jacketed plug valves are suitable for high-temperature and high-pressure conditions, such as in urea, caustic soda, and anhydride production plants, handling gaseous or liquid-solid phase media.)

Jacketed plug valves are by no means general-purpose valves and are primarily used in demanding industrial applications. This is primarily the case in the petrochemical industry, where media that solidify at room temperature, such as asphalt, molten sulfur, and liquid sulfur, require full insulation during transportation and handling. The food processing industry also utilizes jacketed plug valves, where food materials like syrup and honey must be maintained at a specific temperature. Jacketed plug valves are indispensable for transporting high-viscosity media. For example, in the resin and coatings industry, various resins and pigments have high viscosities and are prone to drying, requiring the insulation of jacketed plug valves to maintain fluidity. The jacketed plug valve is a functional valve designed to solve transportation problems under extreme temperature conditions. Through the unique design of the jacket structure, it combines temperature control with the plug valve's excellent flow resistance control ability. When handling high-viscosity and easily drying media, the jacketed plug valve can provide a continuous and reliable transportation process.

(In the metallurgical industry, the jacketed plug valve is used to transport easily solidified media such as asphalt and heavy oil. The jacketed design prevents the media from clogging at low temperatures.)

Full Welded Ball Valve - Fully Welded Design Offer Unparalleled Advantages over Traditional Valves

This is the last one.