Globe valves and check valves are essential components in piping systems, each designed to control fluid or gas flow in distinct ways. While both manage flow, their functions, operations, and applications differ significantly. At KFTE Valves, we offer high-quality solutions for both valve types to meet diverse industrial needs. This guide compares globe valves and check valves, highlighting their differences, advantages, and ideal applications to help you choose the right valve for your system.

A globe valve is a linear-motion valve used to start, stop, or regulate fluid flow in pipelines. It features a spherical body with an internal baffle, a movable disc (or plug), and a stationary seat. By turning a handwheel or actuator, the disc moves to open, close, or throttle the flow, offering precise control. Globe valves are ideal for applications requiring flow regulation, such as in oil and gas, power generation, or HVAC systems. For example, a Cast Globe Valve is often used in general-purpose water systems due to its robust construction.

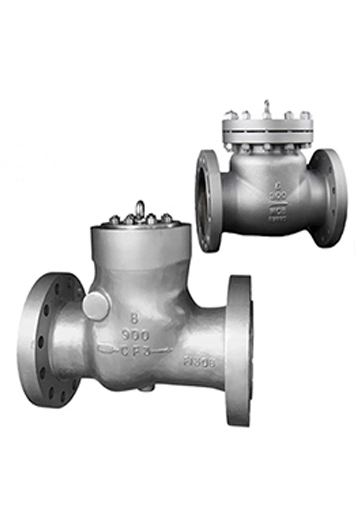

A check valve, also known as a non-return valve, allows fluid or gas to flow in one direction only, automatically preventing backflow. It operates without manual intervention, using pressure differences to open or close the valve. Common designs include swing, lift, and ball check valves. Check valves are critical in systems like water supply lines, sewage systems, or pumps to prevent contamination or equipment damage. For instance, a Cast Check Valve is widely used in plumbing to ensure one-way flow.

While both valves control flow, their design and functionality cater to different needs. Below are the primary differences between globe valves and check valves:

Globe valves are designed for precise flow regulation, allowing users to throttle or completely stop flow. They require manual or automatic operation via a handwheel or actuator. In contrast, check valves operate automatically, opening when upstream pressure exceeds downstream pressure and closing to prevent reverse flow. For example, a Forged Globe Valve might regulate steam in a boiler, while a Forged Check Valve prevents backflow in a pump system.

Globe valves permit bidirectional flow control, depending on their installation and operation. Check valves are unidirectional, allowing flow in one direction only, making them essential for backflow prevention in applications like water treatment.

Globe valves cause a higher pressure drop due to their baffle design, which redirects flow through a tortuous path. Check valves typically have a lower pressure drop, as their design allows smoother flow in the permitted direction, ideal for systems where efficiency is critical.

Globe valves are compact, requiring less installation space, making them suitable for tight spaces. Check valves, especially swing types, may need more room due to their moving parts, such as the disc or flapper, which require clearance to operate.

Globe valves are more complex, with multiple components like the disc, stem, and bonnet, requiring periodic maintenance to ensure sealing integrity. Check valves are simpler, with fewer moving parts, resulting in lower maintenance needs but less versatility in flow control.

| Feature | Globe Valve | Check Valve |

|---|---|---|

| Function | Start, stop, or throttle flow | Prevent backflow |

| Operation | Manual or automatic | Automatic (pressure-driven) |

| Flow Direction | Bidirectional (with control) | Unidirectional |

| Pressure Drop | Higher | Lower |

| Applications | Oil/gas, HVAC, boilers | Water systems, pumps, sewage |

| Maintenance | Higher (complex design) | Lower (simpler design) |

Globe Valves are used where precise flow control is needed, such as:

Industrial Processes: Regulating flow in chemical plants or refineries.

Power Generation: Controlling steam or water in boilers and turbines.

HVAC Systems: Adjusting coolant flow for temperature control.

Check Valves are ideal for preventing backflow in systems like:

Water Supply: Ensuring one-way flow to prevent contamination.

Pumps: Protecting equipment from reverse flow damage.

Sewage Systems: Preventing backups into buildings.

Selecting the right valve depends on your system’s requirements. Consider these factors:

Flow Control Needs: Choose a globe valve for throttling or precise regulation; opt for a check valve for automatic backflow prevention.

Pressure and Flow Conditions: Globe valves suit systems where pressure drop is acceptable, while check valves are better for low-pressure-drop applications.

Media Type: Globe valves are unsuitable for slurries or viscous fluids due to potential clogging; check valves handle a wider range of fluids if designed appropriately.

Space Constraints: Globe valves are more compact, ideal for tight spaces, while check valves may require more room.

Maintenance Capacity: Check valves require less maintenance, making them cost-effective for long-term use in simple systems.

For high-pressure systems, a Forged Check Valve or Forged Globe Valve may be necessary to withstand demanding conditions.

Globe Valves:

Advantages: Precise throttling, bidirectional flow control, compact design.

Limitations: Higher pressure drop, unsuitable for slurries, requires more maintenance.

Check Valves:

Advantages: Automatic operation, low maintenance, effective backflow prevention.

Limitations: No throttling capability, unidirectional flow, potential for leakage at low velocities.

Globe valves and check valves serve distinct roles in fluid systems, with globe valves offering precise flow control and check valves ensuring backflow prevention. Understanding their differences—function, operation, pressure drop, and applications—helps you select the right valve for your needs. At KFTE Valves, we provide high-quality globe valves and check valves tailored for industries like oil and gas, water treatment, and power generation. Explore our catalogs or contact our team at KFTE Valves for expert guidance on your flow control solutions.

Wikipedia. (2025). Globe Valve. An overview of globe valve design and functions. Available at: https://en.wikipedia.org/wiki/Globe_valve.

Wikipedia. (2025). Check Valve. An overview of check valve operations and applications. Available at: https://en.wikipedia.org/wiki/Check_valve.