Plug valves and ball valves are essential quarter-turn valves used for on/off flow control in industrial piping systems. While both provide reliable shut-off, their designs and performance characteristics make them suited for different applications. At KFTE Valves, we offer high-quality plug and ball valves engineered for durability and precision. This guide explores the differences between plug valves and ball valves, covering their designs, sealing mechanisms, and applications to help you choose the right valve for your system.

Plug valves and ball valves are rotary motion valves that control fluid or gas flow with a 90-degree turn of a handle or actuator. Both are designed for quick on/off operation and are not typically used for throttling due to potential damage from partial flow.

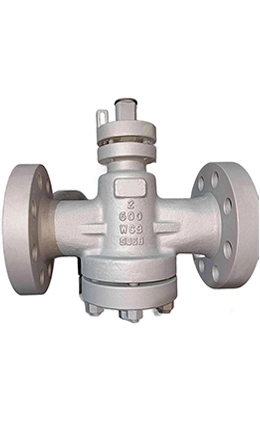

Plug Valve: Features a cylindrical or conical plug with a bored passage. Rotating the plug aligns the passage with the pipeline to allow flow or blocks it to stop flow.

Ball Valve: Uses a spherical ball with a central bore. Rotating the ball aligns the bore with the pipeline for flow or positions it perpendicular to stop flow.

Both valves are compact and reliable, but their structural differences impact their performance, maintenance, and suitability for specific media.

Plug valves and ball valves differ in design, operation, sealing, and application suitability. Below is a detailed comparison.

| Feature | Plug Valve | Ball Valve |

|---|---|---|

| Design | Cylindrical or conical plug with bored passage | Spherical ball with central bore |

| Operation | High torque, harder to actuate | Low torque, easy to operate |

| Sealing | Tighter shut-off (larger sealing surface) | Good shut-off (smaller sealing surface, enhanced by modern sealants) |

| Size/Weight | Smaller but heavier at larger sizes | Compact, lighter overall |

| Actuation | Manual, electric (pneumatic costly) | Manual, electric, pneumatic, hydraulic |

| Maintenance | Easy; plug removable for cleaning | Harder; standard models not serviceable, 3-piece models repairable |

| Longevity | Shorter; larger sealing surface wears faster | Longer; less wear due to low torque |

| Cost | Higher (dependent on size/materials) | Lower (scalable designs) |

| Scalability | Limited | Excellent (multiple types: floating, trunnion, full/reduced bore) |

| Customization | Limited | High (variety of designs and materials) |

| Media Suitability | Slurries, corrosive fluids, low-pressure | High-pressure, high-temperature, sanitary fluids |

| Applications | Sewage, mud, corrosive media | Oil/gas, chemicals, food/beverage, pharmaceuticals |

Design and Construction:

Plug Valve: Uses a cylindrical or conical plug with a rectangular or circular bored passage. The larger plug provides a tighter seal but increases weight, especially in larger sizes.

Ball Valve: Features a spherical ball with a central bore, making it compact and lightweight. The smaller sealing surface is enhanced by advanced chemical sealants.

Operation:

Plug Valve: Requires higher torque due to the plug’s larger surface area and friction, making manual operation more difficult.

Ball Valve: Low torque enables easy operation, ideal for frequent use or automated systems.

Sealing and Shut-Off:

Plug Valve: Offers a tighter shut-off due to a larger sealing surface, excelling in low-density media (e.g., liquids, slurries).

Ball Valve: Provides good shut-off, with modern sealants overcoming smaller sealing surface limitations, suitable for gases and high-pressure fluids.

Maintenance:

Plug Valve: Easier to maintain; the plug can be removed and cleaned, especially in lubricated models.

Ball Valve: Standard models are designed for replacement, not repair. Three-piece ball valves allow servicing but are costlier.

Longevity:

Plug Valve: Larger sealing surface and high torque expose the valve to more wear and corrosion, reducing lifespan.

Ball Valve: Low torque and robust design ensure longer service life, even after periods of disuse.

Cost and Scalability:

Plug Valve: More expensive due to complex design and limited scalability. Available in lubricated (for high-temperature) or non-lubricated (low-temperature) types.

Ball Valve: Cost-effective with excellent scalability, offering varieties like floating, trunnion, full-bore, or reduced-bore designs.

Actuation:

Plug Valve: Primarily manual or electric; pneumatic actuation is possible but costly.

Ball Valve: Supports manual, electric, pneumatic, or hydraulic actuation, enhancing automation flexibility.

Media Compatibility:

Plug Valve: Excels in slurries, sewage, and corrosive media due to tight sealing and corrosion-resistant materials (e.g., stainless steel).

Ball Valve: Suited for high-pressure, high-temperature, or sanitary applications (e.g., oil, gas, food processing) with durable materials.

Both valves operate with a 90-degree (quarter-turn) rotation to control flow, but their internal components differ.

Plug Valve:

Lubricated: Corrosion-resistant with constant lubrication for high-torque, high-temperature systems.

Non-Lubricated: Uses a non-metallic sleeve for low-temperature applications.

Operation: The plug rotates to align its bored passage with the pipeline (open) or block flow with the solid plug section (closed). Lubricated models use grease to reduce friction, while non-lubricated models rely on an elastomeric sleeve.

Example: In a sewage treatment plant, a lubricated plug valve provides quick shut-off for slurry flow.

Types:

Lubricated: Corrosion-resistant with constant lubrication for high-torque, high-temperature systems.

Non-Lubricated: Uses a non-metallic sleeve for low-temperature applications.

Ball Valve:

Floating: Ball floats, sealed by medium pressure, for low-pressure systems.

Trunnion: Ball is fixed, ideal for high-pressure applications.

Full/Reduced Bore: Varies flow capacity based on bore size.

Operation: The ball rotates to align its bore with the pipeline (open) or perpendicular to stop flow (closed). Low torque ensures easy operation.

Example: In a natural gas pipeline, a trunnion ball valve ensures reliable high-pressure shut-off.

Types:

Floating: Ball floats, sealed by medium pressure, for low-pressure systems.

Trunnion: Ball is fixed, ideal for high-pressure applications.

Full/Reduced Bore: Varies flow capacity based on bore size.

Sewage and Wastewater: Handling slurries and mud with tight shut-off.

Chemical Processing: Managing corrosive liquids in low-pressure systems.

Oil and Gas: Controlling flow in pipelines with viscous or dirty media.

Petrochemical: Isolating media with solids in refining processes.

Oil and Gas: High-pressure shut-off in gas lines, crude oil plants, or refineries.

Food and Beverage: Sanitary shut-off in processing lines.

Pharmaceuticals: Sterile flow control in medical production.

HVAC Systems: Managing water or air in heating/cooling systems.

Power Generation: Controlling steam or cooling water in turbines.

Advantages:

Tighter shut-off for slurries and low-density media.

Easy maintenance with removable plug.

Reliable in corrosive or viscous fluid systems.

Limitations:

Higher torque increases operational effort.

Shorter lifespan due to wear on sealing surface.

Limited scalability and customization.

Advantages:

Long-lasting with low torque operation.

Scalable with diverse designs for various applications.

Cost-effective and versatile for high-pressure systems.

Limitations:

Less tight shut-off compared to plug valves (mitigated by sealants).

Standard models not serviceable, requiring replacement.

At KFTE Valves, our plug and ball valves are engineered for performance and reliability:

API-Compliant: Meets API 608 (ball) and API 599 (plug) standards.

Robust Materials: Stainless steel, carbon steel, or corrosion-resistant alloys.

Customizable: Full/reduced bore, lubricated/non-lubricated plugs, manual or actuated.

Low Maintenance: Durable seals minimize downtime.

Competitive Pricing: Cost-effective solutions for industrial needs.

Ready to Optimize Your System? Explore our valve range or request a quote.

Selecting the right valve depends on your application, media, and operational requirements. Use this guide:

Media Type:

Slurries or corrosive fluids: Plug valve for tighter shut-off.

High-pressure or sanitary fluids: Ball valve for durability and versatility.

Pressure and Temperature:

Low-pressure, low-temperature: Plug valve (non-lubricated for low temps).

High-pressure, high-temperature: Ball valve (trunnion for extreme conditions).

Operation Frequency:

Frequent use: Ball valve for low-torque, long-lasting operation.

Infrequent use: Plug valve for reliable shut-off.

Maintenance Needs:

Easy servicing: Plug valve with removable plug.

Long-term reliability: Ball valve, especially 3-piece designs.

Q: What is the main difference between a plug valve and a ball valve?

A: Plug valves use a cylindrical/conical plug with a larger sealing surface for tighter shut-off, while ball valves use a spherical ball with lower torque for easier operation and longer lifespan.

Q: Are plug valves better for slurries than ball valves?

A: Yes, plug valves provide tighter shut-off for slurries and viscous media due to their larger sealing surface.

Q: Can ball valves handle high-pressure systems?

A: Yes, ball valves, especially trunnion designs, are ideal for high-pressure applications like oil and gas pipelines.

Q: Which valve is more cost-effective?

A: Ball valves are generally cheaper and more scalable, making them cost-effective for a wide range of applications.

Plug valves excel in low-pressure applications requiring tight shut-off for slurries or corrosive media, offering easy maintenance but higher torque and shorter lifespan. Ball valves are versatile, cost-effective, and long-lasting, ideal for high-pressure, high-temperature, or sanitary systems with low-torque operation. Understanding these differences ensures optimal valve selection for your piping system. KFTE Valves provides API-compliant plug and ball valves, engineered for reliability and performance.

Ready to enhance your fluid control system? Explore KFTE's valve range or contact us for a tailored solution today!