The KFTE Concentric Butterfly Valve available in both flanged, wafer and lug design and with high quality rubber liner that significantly increases the service life. The one-piece replaceable liner also serves as a profiled flange gasket and comes in either drinking water approved EPDM, high temperature EPDM or hydrocarbon resistant NBR. Disc material is stainless steel or epoxy coated ductile iron. The shaft in stainless steel, installed in low friction bronze/PTFE bearings in an anti-blow out design plus the unique disc sealing profile results in low operating torque and long life. KFTE concentric butterfly valves are widely used in various industrial fluid control applications. The fully rubber-encapsulated body is suitable for various corrosive service conditions.

TECHNICAL SPECIFICATIONS

Pressure: ANSI 125/150LB, PN1.0/PN1.6MPa

Size: 2″~96″ (50~2400mm)

Materials: A126 B (GG25), A536 65-45-12 (GGG40)

Epoxy coating with thickness ≥ 250μm

Applicable medium: water, sewage, sea water, air, corrosive liquids

Applicable temperature: -45℃~+150℃ (higher temperature is available upon request)

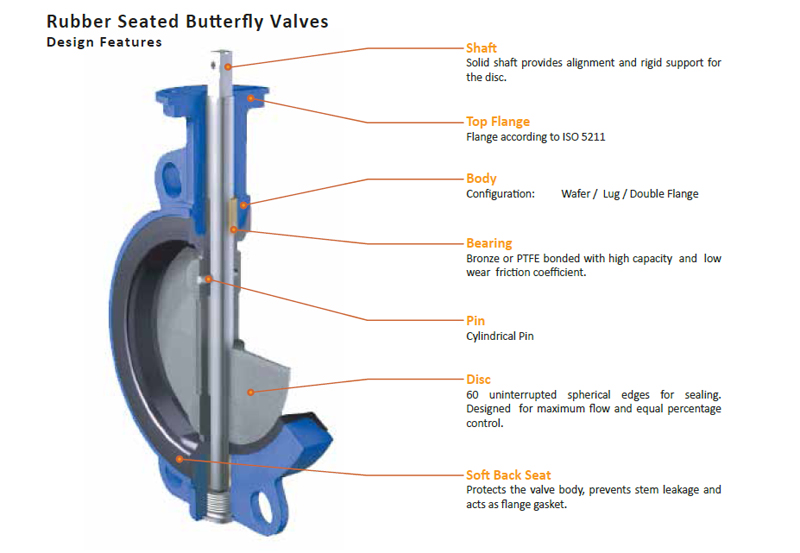

1. Polished disc edge provides full concentric sealing with lower torque and long service life.

2. Bi-directional sealing which is suitable for normal flow and contraflow working condition.

3. Cylindrical pin enables a vibration free connection between the shaft and the disc.

4. Rubber seats vulcanized on the body in such a way that the seats protrude a little outside the valve body (this eliminates need for a flange gasket).

5. Replaceable seal held with seat ring on the disc allows easy maintenance.