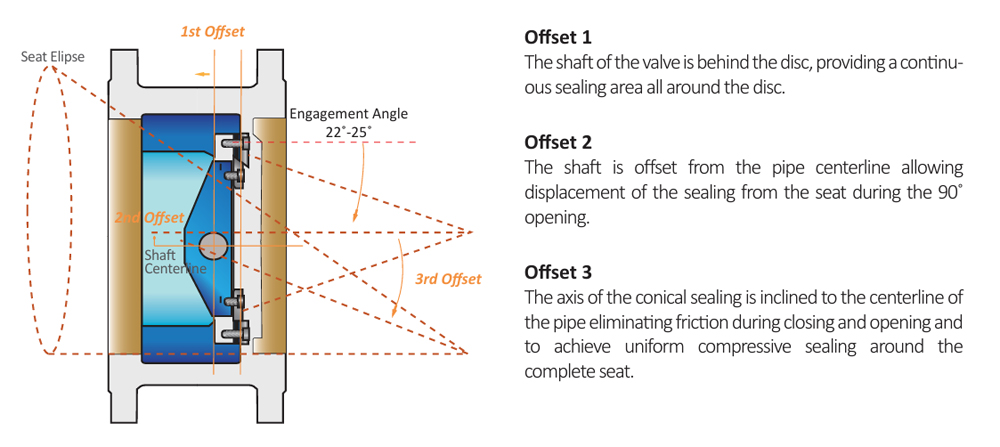

KFTE metal-seated Triple Offset butterfly valve as a good solution for the toughest industrial applications. KFTE's Triple Offset butterfly valve offers a light-weight, cost-effective, and compact design with a low operating torque. They are metal-seated design, featured with quarter-turn, bi-directional, and Zero-Leakage properties. Due to it's metal sealing, it is inherently fisafe and can completely eliminate traditional butterfly leakage problems due to seat aging or deformation. A wide range of available body materials make the metal-seated Triple Offset butterfly valve not only good for isolation service, but also ideal for most process & control applications.

Design Standards

Design Standard: API 609

Size: 3"(DN80)-96"(DN2400) Pressure: 150LB-600LB / PN16- PN100 Material: WCB, WCC, WC6, WC9, C5, C12, C12A, LCB, LCC, LC1, LC3, CF8, CF8M, CF3, CF3M, CF8C

Flanged End Connection: ASME B16.5 / ASME B16.47; EN1092-1

Face-to-Face: API 609 / ASME B16.10

Test & Inspection: API 609 / ASME B16.10

Fire-Safe: API 607

Low Fugitive Emission: ISO 15848-2015

NACE Construction: MR 0715

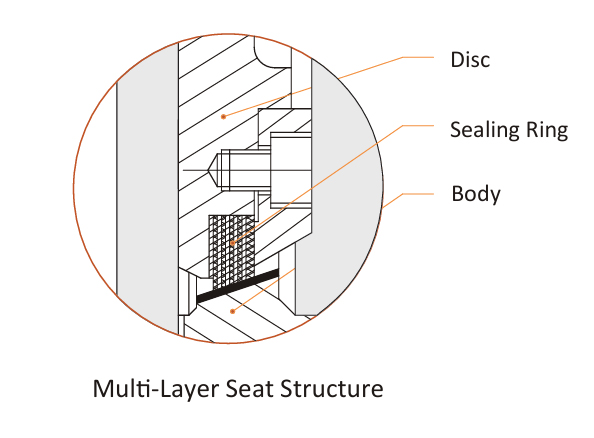

Seat Design

Both Full PTFE Seat and Multi-Layer Seat are available.

Multi-layer sealing is made of composite layers of Stainless Steel and Non-metal material.

Non-metal material can be Flexible Graphite, PTFE, or other material depending on the media and operating conditions.

1. The Triple Offset design provides Zero Leakage Seat Tightness to API 598 resilient seat standard.

2. Anti-blowout stem for high dependability, completely conforming to API609.

3. Inherently fire-safe for multi-layer metal seat.

4. Tested for Low Fugitive Emission according ISO 15848-2015.

5. Extended Bonnet available for Cryogenic applications.

| Material Specification | ||||

| NO. | DESCRIPTION | CARBON STEEL | SS304 | SS316 |

| 1 | END CAP | A105 | A182 F304 | A182 F316 |

| 2 | BOLT | A193 B7 | A193 B8M | A193 B8M |

| 3 | GASKET | FLEXIBLE GRAPHITE | FLEXIBLE GRAPHITE | FLEXIBLE GRAPHITE |

| 4 | AXLE SLEEVE | SF-1 | SF-1 | SF-1 |

| 5 | BODY | A216 WCB | A351 CF8 | A351 CF8M |

| 6 | DISC | A216 WCB | A351 CF8 | A351 CF8M |

| 7 | SEAL RING | SS304+GRAPHITE | SS304+GRAPHITE | SS304+GRAPHITE |

| 8 | GLAND | A105 | A182 F304 | A182 F316 |

| 9 | BOLT | A193 B7 | A193 B8M | A193 B8M |

| 10 | PIN | A182 F6A | 17-4PH | 17-4PH |

| 11 | SHAFT | SS410 | SS410 | SS410 |

| 12 | AXLE SLEEVE | SF-1 | SF-1 | SF-1 |

| 13 | PACKING | FLEXIBLE GRAPHITE | FLEXIBLE GRAPHITE | FLEXIBLE GRAPHITE |

| 14 | PACKING GLAND | A216 WCB | A351 CF8 | A351 CF8M |

| 15 | SPRING GASKET RING | A194 2H | A194 8M | A194 8M |

| 16 | NUT | AISI 1065 | AISI 1065 | AISI 1065 |

| 17 | BOLT | A193 B7 | A193 B8M | A193 B8M |

| 18 | YOKE | CARBON STEEL | CARBON STEEL | CARBON STEEL |

| 19 | SPRING GASKET RING | AISI 1065 | AISI 1065 | AISI 1065 |

| 20 | BOLT | A193 B7 | A193 B8M | A193 B8M |

| 21 | GEAR | - | - | - |