3-way ball valves are versatile components in industrial fluid control systems, offering precise flow direction and mixing capabilities. At KFTE Valves, we provide high-performance 3-way ball valves engineered for durability and efficiency. This guide answers key questions about 3-way ball valves, including how they work, their uses, differences from 2-way valves, and directional control, helping you select the right valve for your application.

A 3-way ball valve is a quarter-turn valve with three ports, used to direct, divert, or mix fluid flow in piping systems. Unlike traditional 2-way valves, which control flow between two ports, 3-way valves offer greater flexibility with two main configurations: L-port and T-port. These configurations determine how fluid flows through the valve, making them ideal for complex flow control tasks.

A 3-way ball valve operates by rotating a ball with a bore (cut-out channel) inside the valve body to align with the ports. The handle, which is turned 90° or 180°, controls the ball's position, directing fluid flow based on the bore's shape (L or T).

Ball Rotation: The handle rotates the ball, aligning the bore with the inlet and outlet ports.

Flow Direction:

L-Port: Directs flow from one inlet to one of two outlets (90° diversion) or shuts off flow completely.

T-Port: Directs flow from one inlet to one or both outlets, mixes flow from two inlets to one outlet, or diverts flow without shut-off.

Sealing: The ball's tight fit against seats ensures leak-proof operation in open or closed positions.

A 3-way directional valve is a type of 3-way ball valve used to control the direction of fluid flow in systems requiring precise routing. It works similarly to a standard 3-way ball valve but is often designed for specific directional control tasks, such as in hydraulic or pneumatic systems.

Precise Positioning: The valve’s ball can be rotated to exact positions (e.g., 0°, 90°, 180°) to direct flow to specific ports.

Actuation Options: Manual (handle), pneumatic, or electric actuators for automated control.

Flow Patterns: L-port for switching between two outlets; T-port for mixing or splitting flows.

In a hydraulic system, a 3-way directional valve might switch fluid from a pump to one of two actuators (L-port) or combine flows from two sources into one line (T-port). The valve's quick quarter-turn operation ensures rapid and reliable flow redirection.

3-way ball valves are used in applications requiring flow diversion, mixing, or shut-off. Their versatility makes them essential in various industries.

Flow Diversion: Redirects fluid from one source to two different destinations (e.g., switching between two tanks).

Flow Mixing: Combines two fluid streams into one outlet (e.g., blending hot and cold water).

Shut-Off: Stops flow completely (L-port only).

Bypass Control: Allows flow to bypass a system component (e.g., a filter) for maintenance.

Process Selection: Switches between different process lines in chemical or pharmaceutical plants.

HVAC Systems: Mixing hot and cold water for temperature control.

Chemical Processing: Diverting or mixing reactive fluids.

Oil and Gas: Routing fluids between pipelines or storage tanks.

Water Treatment: Directing flow to different treatment stages.

Food and Beverage: Managing ingredient flows in hygienic systems.

Pharmaceuticals: Controlling precise fluid mixing in sterile environments.

2-way and 3-way ball valves serve different purposes based on their port configurations and flow control capabilities. Below is a detailed comparison.

| Feature | 2-Way Ball Valve | 3-Way Ball Valve |

|---|---|---|

| Number of Ports | 2 (inlet and outlet) | 3 (one inlet, two outlets or vice versa) |

| Flow Control | On/off or throttling | Diversion, mixing, or shut-off |

| Bore Shape | Straight-through | L-shaped or T-shaped |

| Shut-Off Capability | Yes, complete shut-off | L-port: Yes; T-port: No |

| Applications | Simple flow control (e.g., pipelines) | Complex flow routing (e.g., mixing, diversion) |

| Cost | 15-25% cheaper | Higher due to complex design |

| Space Requirement | Compact | Slightly larger due to third port |

| Best For | Basic on/off tasks | Systems needing flow direction control |

Port Configuration:

2-Way: Two ports for straight-through flow (open or closed).

3-Way: Three ports for diverting or mixing flows, with L-port or T-port options.

Functionality:

2-Way: Primarily for on/off control or throttling in simple systems.

3-Way: Enables complex tasks like switching between outlets, mixing fluids, or bypassing components.

Shut-Off:

2-Way: Always provides complete shut-off.

3-Way: L-port allows shut-off; T-port cannot shut off all ports without additional valves.

Applications:

2-Way: Used in pipelines, irrigation, or basic fluid control.

3-Way: Suited for HVAC, chemical processing, or systems requiring flow redirection.

Cost and Complexity:

2-Way: Simpler and cheaper (15-25% less than 3-way).

3-Way: More expensive due to additional port and complex ball design.

3-way ball valves come in two primary configurations, each suited for specific flow patterns.

Bore Shape: L-shaped, connecting two adjacent ports at a 90° angle.

Functions:

Diverts flow from one inlet to one of two outlets.

Shuts off flow completely.

Applications: Switching between two process lines or tanks (e.g., in water treatment).

Limitations: Cannot mix flows or connect all three ports simultaneously.

Bore Shape: T-shaped, connecting two or three ports depending on position.

Functions:

Diverts flow from one inlet to one or both outlets.

Mixes flows from two inlets to one outlet.

Splits flow from one inlet to two outlets.

Applications: Blending fluids in chemical or HVAC systems.

Limitations: Cannot shut off all ports without additional valves.

| Feature | L-Port | T-Port |

|---|---|---|

| Bore Shape | L-shaped | T-shaped |

| Flow Patterns | Divert or shut-off | Divert, mix, or split |

| Shut-Off | Yes | No (requires additional valves) |

| Mixing Capability | No | Yes |

| Best For | Switching between lines | Blending or splitting flows |

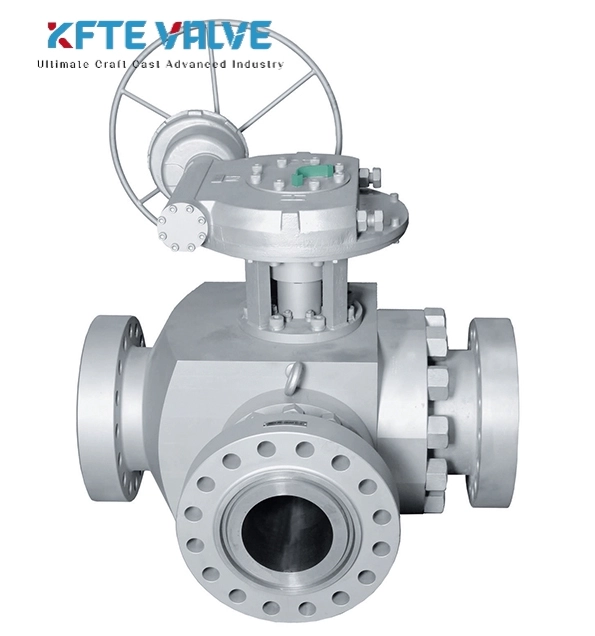

At KFTE Valves, our 3-way ball valves are designed for reliability and performance:

Durable Materials: Stainless steel, carbon steel, or PVC for corrosive or hygienic applications.

Precision Engineering: Tight sealing and accurate flow control.

Customizable Options: L-port or T-port, manual or actuated, with unions or flanges.

Easy Maintenance: Union connections for quick servicing.

API-Compliant: Meets industry standards for safety and quality.

Ready to Optimize Your System? Explore our 3-way ball valve range or request a quote.

Choosing the right 3-way ball valve depends on your application, fluid properties, and system requirements. Use this guide:

Flow Requirement:

Diversion or shut-off: Choose L-port.

Mixing or splitting: Choose T-port.

Fluid Type:

Corrosive fluids: Use stainless steel or PVC valves.

Non-corrosive: Carbon steel or brass may suffice.

Pressure and Temperature:

High-pressure (>300 psi) or high-temperature (>200°C): Select API-compliant valves.

Low-pressure/temperature: Standard valves are sufficient.

Actuation:

Manual for simple systems.

Pneumatic/electric for automated control.

Maintenance Needs:

Choose valves with unions or flanges for easy servicing.

Q: How does a 3-way ball valve differ from a 2-way ball valve?

A: A 2-way ball valve has two ports for on/off control, while a 3-way ball valve has three ports for diverting, mixing, or shutting off flow, with L-port or T-port configurations.

Q: Can a T-port 3-way valve shut off all ports?

A: No, T-port valves cannot shut off all ports without additional valves. Use an L-port valve for complete shut-off.

Q: What indicates the flow direction in a 3-way ball valve?

A: The handle’s T- or L-shaped arrow mimics the ball's bore, showing which ports are connected.

Q: Are 3-way ball valves suitable for mixing fluids?

A: Yes, T-port 3-way valves are ideal for mixing fluids, but consistent pressure in feed lines is needed for accurate mixing.

3-way ball valves are essential for directing, mixing, or shutting off fluid flow in complex systems. L-port valves excel in diversion and shut-off tasks, while T-port valves are ideal for mixing or splitting flows. Compared to 2-way ball valves, 3-way valves offer greater flexibility for applications in HVAC, chemical processing, and oil and gas. KFTE Valves provides durable, API-compliant 3-way ball valves tailored to your needs, ensuring efficiency and reliability.

Ready to enhance your fluid control system? Explore KFTE’s 3-way ball valves or contact us for a tailored solution today!