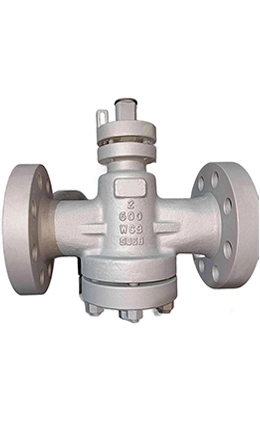

A plug valve is based on a plug with a hollow passage in the valve body. The quarter-turn motion creates an alignment between the pipe and the hole, leading to an open state. When turned to a 90-degree angle from the open position, the valve sits across the pipe leading to a closed state. KFTE plug valves can be divided into five major groups, depending on their functionality. These groups are lubricated, sleeved plug valve, multi-port, double block & bleed and eccentric. Design & Manufactured to API 6D, API 594, ASME B16.34 or Equivalent. Pressure Ratings from Class 150 to Class 2500, PN16 to PN420. Sizes Ranges from 1/2”thru 60”. A variety of body and trim material is offered, including Carbon Steel, Low Temperature Carbon Steel, High Temperature Alloy Steel, Stainless Steel, Duplex & Super Duplex Steel.

1. Simple and Robust Design

Compact construction with fewer components, reducing failure points.

Tapered or cylindrical plug ensures tight shutoff even in high-pressure or abrasive conditions.

Durable materials (e.g., cast iron, stainless steel, alloy coatings) resist corrosion and wear.

2. Excellent Shutoff Capability

Metal-to-metal sealing (in lubricated plug valves) provides bubble-tight closure for critical applications like gas pipelines or chemical processing.

Non-lubricated designs use elastomer sleeves for zero-leakage performance in clean fluids.

3. Versatile Flow Control

Multi-port configurations (2-way, 3-way, 4-way) enable diverting, mixing, or splitting flow in a single valve.

Example: 3-way plug valves route fluids between tanks or processes without additional piping.

Full-bore design minimizes pressure drop, ideal for slurries, viscous fluids, or solids-laden media.

4. Low Maintenance and Easy Repair

Top-entry design allows access to internal components (plug, seats) without removing the valve from the pipeline.

Lubricated plug valves can be re-greased in-service to extend lifespan in harsh environments.

5. High-Pressure and Temperature Tolerance

Suitable for Class 150 to 2500 (ASME) and temperatures from -50°C to 540°C, depending on materials.

Common in steam systems, refinery pipelines, and high-temperature hydrocarbon processing.

6. Adaptability to Challenging Media

Handles abrasive slurries (e.g., mining, wastewater), viscous fluids (e.g., crude oil, asphalt), and corrosive chemicals (e.g., acids, caustics).

Fire-safe designs (API 607/6FA) prevent failure in emergency scenarios.

1. Design and Operation

Plug Valve:

Closure Mechanism-Uses a cylindrical or conical plug with a bore that aligns with ports. The plug rotates 90° or 180° to control flow.

Sealing-Metal-to-metal sealing (lubricated designs) or elastomer sleeves for tight shutoff. Ideal for abrasive or viscous media.

Flow Path-Often multi-port (3-way, 4-way) for diverting, mixing, or splitting flow.

Ball Valve:

Closure Mechanism-Employs a rotating ball with a through-hole. The ball turns 90° to open/close flow.

Sealing-Soft seals (PTFE, rubber) or metal seals for zero leakage. Better for high-pressure systems.

Flow Path-Primarily 2-way, though 3-way designs exist (L/T-port) for diverting or mixing.

2. Maintenance and Applications

Plug Valve:

Maintenance: Top-entry design allows in-line repairs without pipeline removal. Lubricated types require periodic greasing 7.

Applications:

Oil & gas pipelines (crude oil, sour gas).

Chemical processing (acid transfer, abrasive slurries).

Water treatment (sludge control)

Ball Valve:

Maintenance: Side/top-entry designs simplify component access. Minimal friction reduces wear 27.

Applications:

High-pressure steam systems (power plants).

LNG cryogenic systems.

HVAC and general-purpose flow control