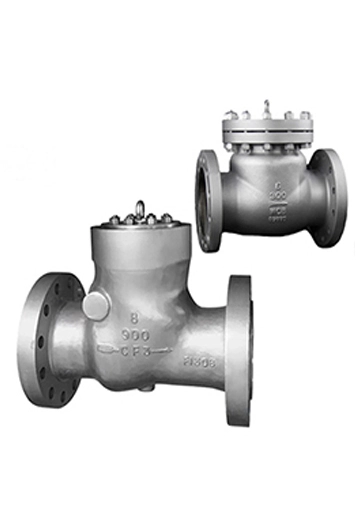

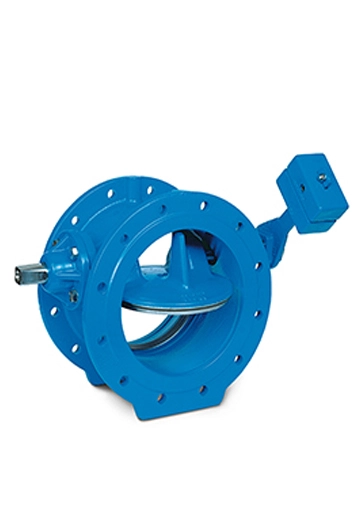

KFTE is a proud check valve manufacturer and supplier that provide industrial check valves in various configurations and materials, including bronze, steel, and iron valves. Our check valves are industry approved for a wide range of applications, from oil & gas to pulp & paper. KFTE check valves available in sizes from 2″ – 48″ and class ratings 150 through 2500. Our check valve is tested vigorously to API 598 and design standard ANSI B16.34. All of our products are supplied with EN10204 3.1 Test Certification. Further testing is available on customer request such as; radiography testing and Non-destructive Testing (NDT). KFTE also offer Check Valves in a large selection of exotic materials including; Chrome Moly Alloy, Duplex, Aluminum Bronze, Monel, Inconel and Titanium.

The check valve in a well pump system is a critical component that prevents water from flowing backward (backflow) into the well when the pump shuts off.

1. Submersible Well Pump Systems

Primary Check Valve:

Located directly above the submersible pump in the drop pipe (the pipe that carries water up from the well).

Often integrated into the pump itself or installed as a separate valve just above the pump.

Additional Check Valves:

In deep wells (over 100–200 feet), multiple check valves may be spaced along the drop pipe to reduce pressure on the primary valve and prevent water column backflow.

2. Jet Pump Systems (Shallow or Deep Wells)

Foot Valve:

Acts as the check valve and is located at the bottom of the well (submerged in water) on the suction pipe.

Combines a check valve with a strainer to block debris.

Secondary Check Valve:

Sometimes installed near the pump inlet (above ground) to maintain prime and prevent backflow into the well.

3. Common Locations Across Systems

Near the Pump: Either integrated into the pump housing or directly above/below it.

In-Line on the Drop Pipe: For submersible pumps, check valves may be installed at intervals in the vertical pipe.

At the Pressure Tank: Some systems include an above-ground check valve near the pressure tank to protect the pump from backflow.

Key Functions of the Check Valve:

Maintains prime in the pump by keeping water in the pipes.

Prevents water hammer (sudden pressure surges) from backflow.

Reduces wear on the pump by avoiding repeated cycling to re-prime.

Check valves should be installed in systems where backflow prevention is critical to protect equipment, maintain efficiency, or ensure safety.

1. Pump Systems

To Maintain Prime: Install a check valve on the discharge side of a pump (e.g., well pumps, sump pumps) to prevent water from flowing backward and losing prime.

Example: A foot valve (a type of check valve) is placed at the bottom of a well’s suction pipe.

Multiple Pumps in Parallel: Use check valves to prevent fluid from backflowing into idle pumps, which could cause damage or reverse rotation.

2. Preventing Reverse Flow

Gravity-Driven Systems: Install check valves in vertical pipes or elevated tanks to stop gravity from reversing flow when pumps shut off.

Pressure Variations: In systems with fluctuating pressure (e.g., boiler feed lines, compressed air systems), check valves prevent reverse flow during pressure drops.

3. Protecting Equipment

Contamination Prevention: Use check valves to keep contaminated fluids from flowing backward into clean water supplies (e.g., wastewater treatment, chemical processing).

Water Hammer Mitigation: Check valves reduce sudden pressure surges caused by abrupt pump shutdowns or valve closures.

4. HVAC and Plumbing Systems

Hot Water Recirculation: Prevent cold water from entering hot water lines.

Boiler Systems: Stop condensate from flowing back into steam lines.

Solar Thermal Systems: Avoid reverse circulation at night when the pump is off.

5. Industrial and Process Applications

Chemical Injection: Ensure chemicals flow in one direction to avoid mixing or reactions in upstream lines.

Fuel Systems: Prevent fuel from draining back into storage tanks (e.g., diesel generators, aircraft fueling).